- WhatsApp:+86-19892834301

- Email: automantool@hotmail.com

- Skype:autoobdtop

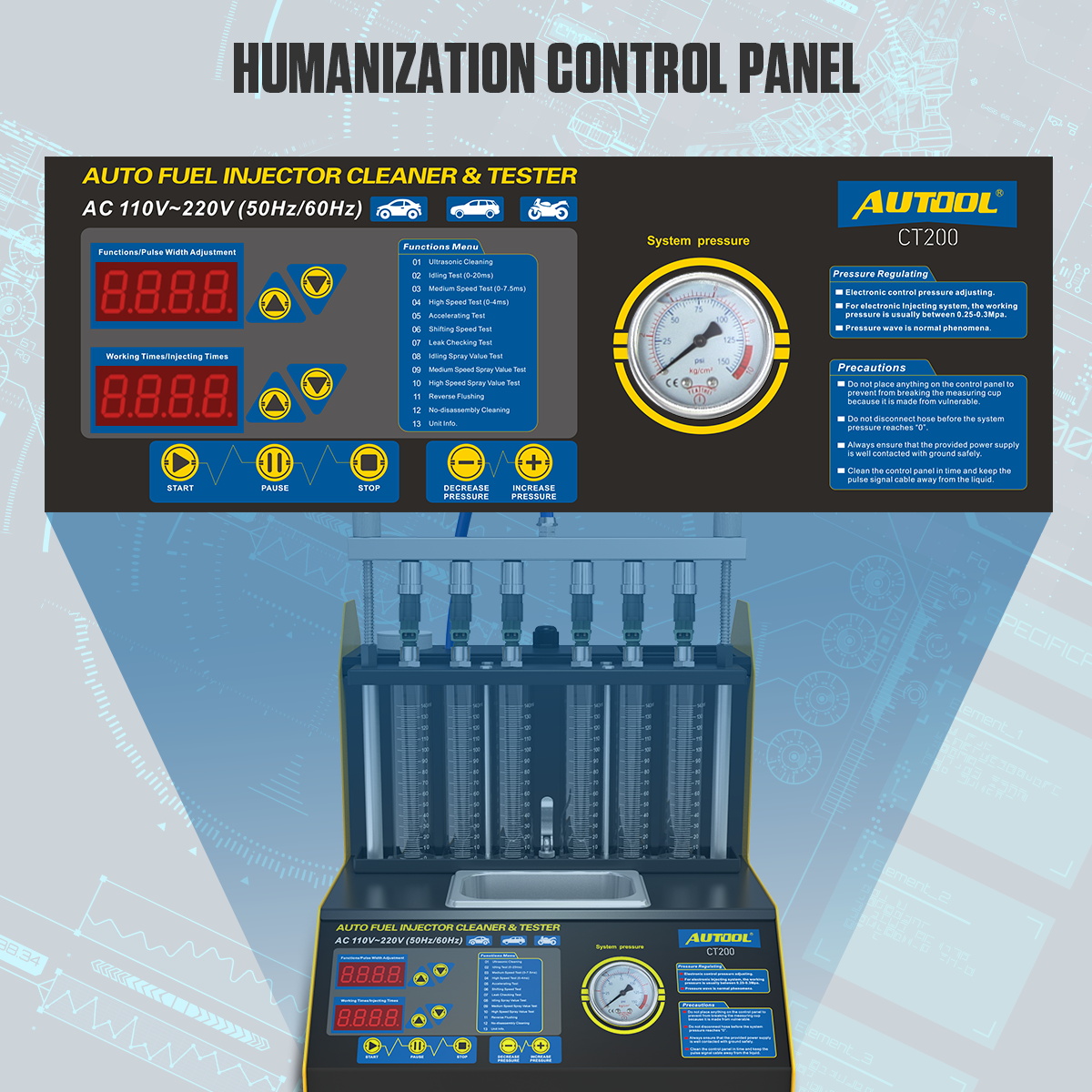

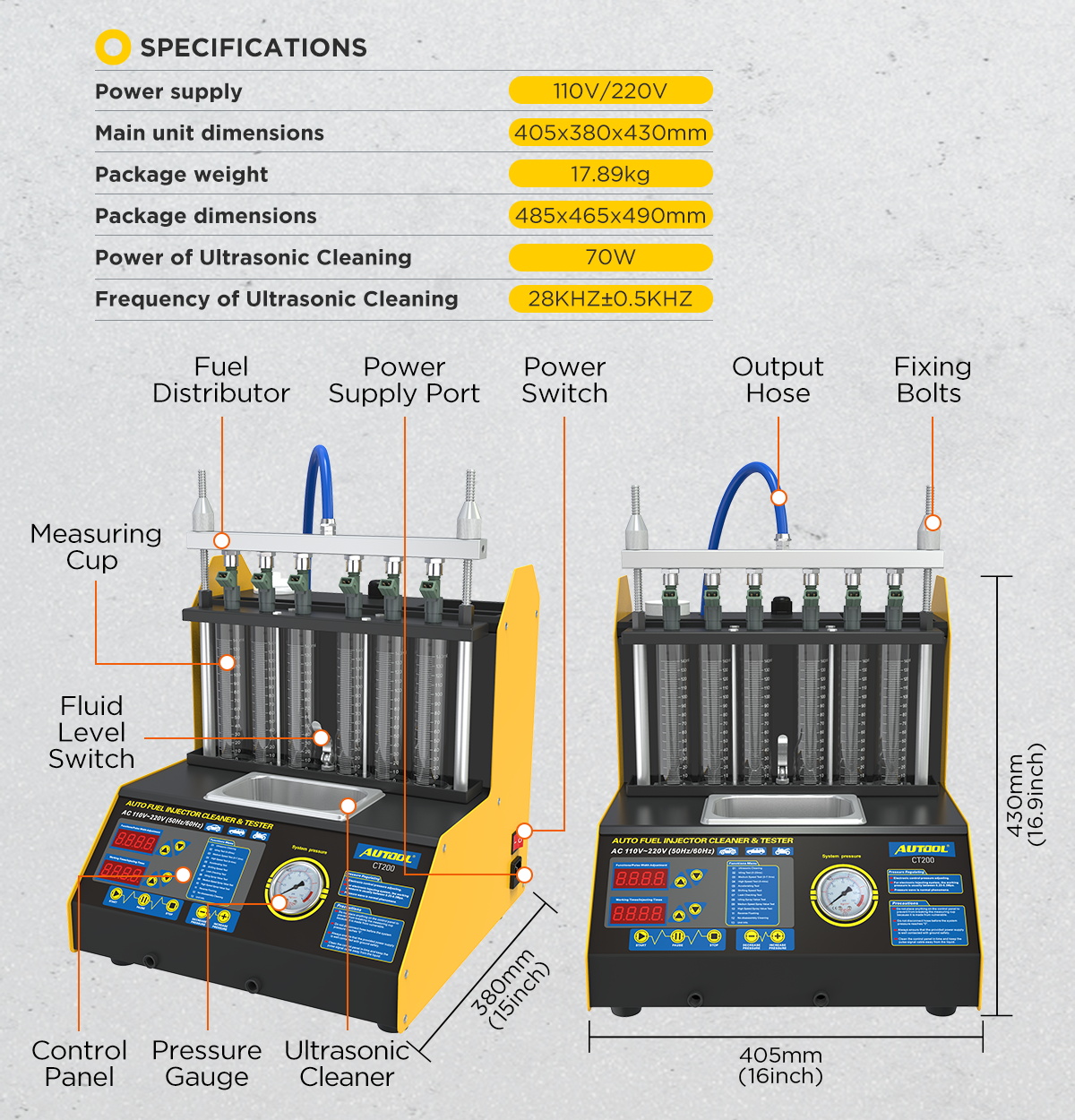

AUTOOL CT200 Ultrasonic Fuel Injector Cleaner & Tester Support 110V/220V with English Panel & FSI HPI GDI Injector

0 out of 50 global ratings

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

ratings| answered questions

0 global ratings

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

Fast Shipping & No Tax

US Check: Ship from US

UK Check: Ship from UK

EU Check: Ship from Czech

Looking for help? Please contact Whatsapp: +86-19892834301

- Shipping:

-

Free Shipping

Express Shipping ServiceEstimated delivery time: 3-5 Working Days

- Quantity:

- Stock:28

- Weight:

- 18 KG

- Package:

Related Download Files

AUTOOL CT200 Ultrasonic Fuel Injector Cleaner

Support For 99% Car Model

Support for Audi,for Australia Ford,for Benz,for BMW,for Brilliance,for Chevrolet,for Chevy,for Chrysler,for Citroen,for Dacia,for Dadi,for Daewo,for Daihatsu,for Demo,for Fiat,for Ford,for GM,for Holden,for Honda,for Hyundai,for Isuzu,for Jaguar,for Kia,for Lancia,for Land Rover,for Mahindra,for Maruti,for Mazda,for Mitsubish,for Nissan,for Opel,for Peugeot,for Porsche,for Renault,for Romeo,for Rover,for Saab,for Seat,for Skoda,for Smart,for Subaru,for Suzuki,for Tata,for Toyota,for Volvo,for VW,for Yamaha,etc.

About Machine Details

English manual & English control panel;

Power

cord:110V and 220V;

3 Years Warranty.

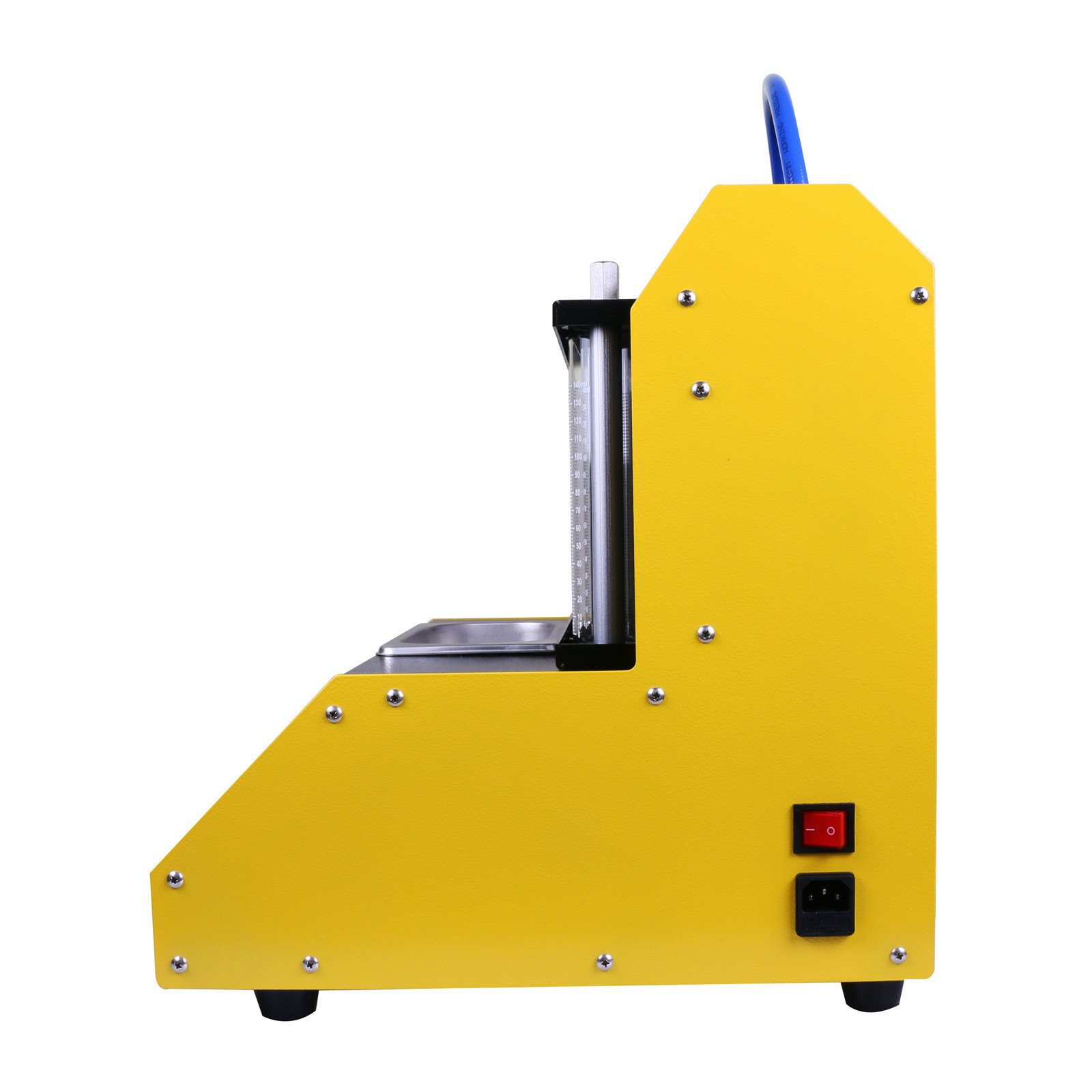

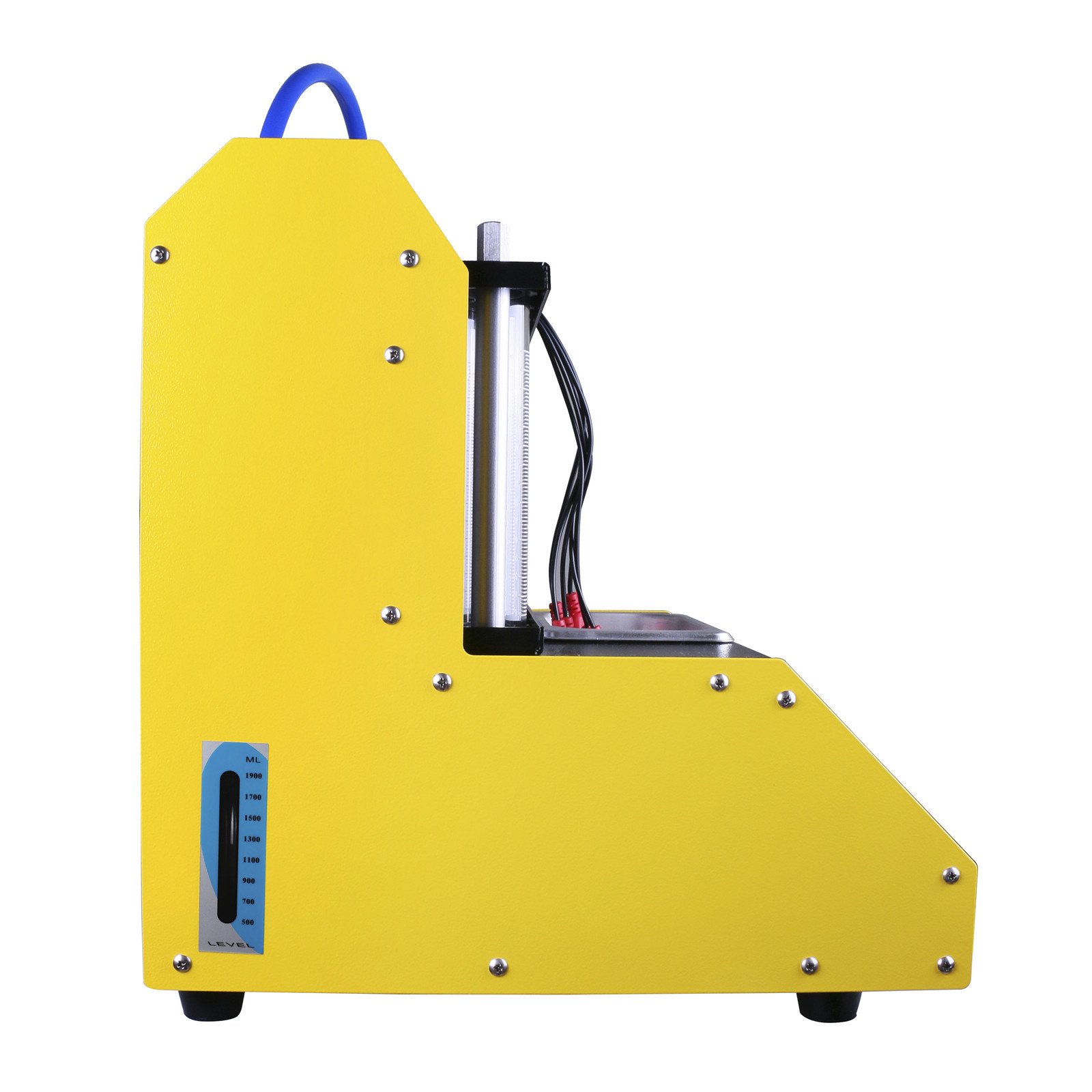

The AUTOOL CT200 injector

cleaning and testing machine is designed with wide voltage technology and is

suitable for 110V and 220V voltage.It is combined with ultrasonic cleaning

technology and microprocessor hydraulic control cleaning detection technology.

Fuel pump oil supply simulates low, medium and high engine conditions, cleaning

and testing the fuel injectors of the automobile; ultrasonic cleaning can

simultaneously clean multiple injectors, which can effectively and completely

remove carbon deposit for the automobiles injectors.

Note: Injector cleaning agent test liquid and cleaning

agent precautions why have to clean injector? When we turned off the engine suddenly, the gasoline

which have been spray out can not be recycled. It would attached on the injector

and combustion chamber walls. Gasoline is easy to volatile, but wax and varnish

were stayed. Heat these wax and varnish day after day,they will be changed into

hard coke. The hard coke will be produced more quickly and more thickly when

engine work with poor quality fuel. Tips: Do not get any cleaning solvent on the

outside of the vehicle, as this will damage the paint. A heavily clogged fuel

injector may not allow enough cleaner to pass through during a routine cleaning

to be adequately cleaned. Additional cleanings may be needed to clear heavy

deposits. How to Work ? 1. Clean injector's outside with gasoline or cleaning

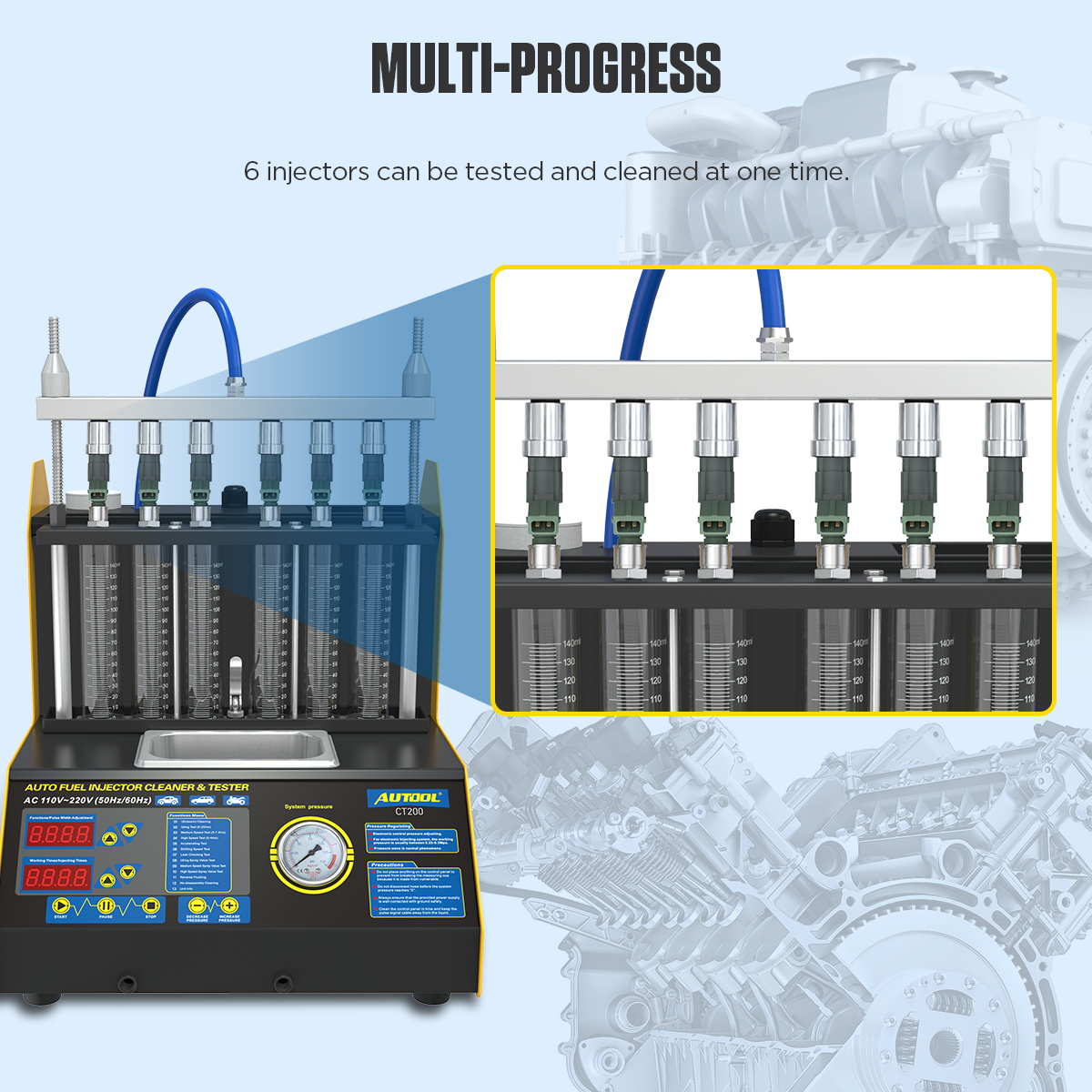

liquid before open machine FUNCTIONS: AUTOOL CT200 Fuel Injector Cleaner & Tester is with

English Panel. We can clean and test both petrol car and motorcycle injector

with this machine. (motorcycle support HONDA YAMAHA SUZUKI SANYANG only)

Package include: 1 x CT200 Unit Points: Ultrasonic cleaning:

1. It is forbidden to use corrosive liquids as

fuel injection nozzle detection liquid to detect fuel injection nozzles.

Corrosive liquids will damage machine seals and fuel injectors;

2. It is

forbidden to use a cleaning agent instead of the detection liquid, because the

cleaning agent is generally corrosive and will cause damage to equipment and

injector seals;

3. It is forbidden to use gasoline instead of cleaning agent

or test liquid, which is dangerous and easy to cause safety hazards;

4.

Please use absolute ethanol (industrial alcohol) or other non-corrosive liquids

as the detection liquid (generally the detection liquids are colorless and

transparent, no irritating odor liquid);

What is a cleaning

agent?

The cleaning agent is used to clean the attachments (carbon

deposits) on the fuel injection nozzle. It is generally highly corrosive and

flammable. It should be kept away from the fire source and avoid contact with

the skin when used. Use it in the ultrasonic cleaning tank of the injector

cleaner;

What is a test solution?

The test liquid is used

to test and judge the quality of the fuel injection nozzle. It is a colorless

and transparent liquid with no irritating odor, non-corrosiveness, and not easy

to emit, but used in the measuring cylinder of the fuel nozzle cleaning

machine;

2 Putting injectors in ultrasonic bathtub after

the outside of injector are free of dirt.

3 Turn on ultrasonic system,pulsed

allowing the ultrasonic energy to dislodge any particles even build-up inside

the injectors.

4 Fixed injectors on main machine

5 Testing injectors for

resistance, shorts, and current draw

6 Performing leak test, spray pattern,

and flow rate testing on flow bench.

7 The injectors are now returned to the

flow bench for retesting of all functions.

1.Ultrasonic cleaning , dismantle the carbide of the injector;

2.injector test. stimulate engine runing condition, test injector in

different speed range, Check and test injectors's injection

situation:atomization/sprayingangle/spraying mount/spraying uniformity;

3.leakage and block test;

4.Uniquely designed various compound bonder

for all kinds of side-inlet injectors;

5.With reverse flush function, to

clean inside out, to improve clean efficiency;

6.With a set of adaptors to

clean injectors without dismantling it from the engine;

2 x Valve (for discharging fluid from

machine tank)

6 x Adapter for fixing injector on machine

6 x linkage

6 x Blocker for block distributor

1 x Distributor Kits

1 x Impulse

cable for providing power to open injector

1 x

Manual(English)

1.The cleanser added into the

ultrasonic cleaner just soaked the injectors' needle is suitable.

2.Before

the ultrasonic cleanser is added into ultrasonic cleaner, do not turn on the

ultrasonic cleaner. Otherwise, damage may be incurred.

3.Strictly prohibit

to put the pulse signal cable or its connecter into the cleanser, otherwise

damage will be incurred.

4.The continue work time of the ultrasonic cleaner

don't be more than 30min, otherwise it will shorten the life.

5.Not in

using, please put out the power plug.

Uniformity/Sprayability Test:

Under this function, the parameters of RPM, PW and time can be adjusted in real

time.

Leakage Test: Under this function, the parameter of fuel

pressure can be adjusted in real time.

Injecting Flow Test: Under

this function, the parameter of fuel pressure can be adjusted in real time.

Auto mode Test: Under this function, the parameter of fuel pressure

can be adjusted in real time.

0 Stars of 5,0 Reviews.

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

Share your thoughts with other customers.

Write a reviewYou may also like

-

5D wheel alignment machine FCAR FD-505 wheel aligner support all car lifts portable aligner garage equipment and tools

$7999.001% off

-

Launch TLT840WA 4 Tons Double Scissor Lift Suitable For Small Passenger Cars and Light Trucks

$4099.002% off

-

Tektino INJ-8B 8 Cylinders Fuel Injector Cleaning Machine For Gasoline Engines for Automotive Repair Clean And Test

$989.007% off

-

Launch CNC603A Exclusive Ultrasonic Fuel Injector Cleaner Cleaning Machine 46 Cylinder Fuel Injector Tester 220V110V

$629.005% off

-

SmartSafe X-431 X431 ADAS LITE ADAS Calibration Machine

$1999.005% off

-

ANCEL ANJ400 GDI Car Fuel Injector Cleaner Tester 4 Cylinders EFI FEI Petrol Injection Nozzles Ultrasonic Cleaning Testing Tool

$349.005% off

-

TLT240SC Clear Floor Two Post Lift

$1438.001% off

-

Tel

+86-19892834301 -

WhatsApp