- WhatsApp:+86-19892834301

- Email: automantool@hotmail.com

- Skype:autoobdtop

ANCEL ANJ400 GDI Car Fuel Injector Cleaner Tester 4 Cylinders EFI FEI Petrol Injection Nozzles Ultrasonic Cleaning Testing Tool

0 out of 50 global ratings

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

ratings| answered questions

0 global ratings

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

Fast Shipping & No Tax

US Check: Ship from US

UK Check: Ship from UK

EU Check: Ship from Czech

Looking for help? Please contact Whatsapp: +86-19892834301

- Shipping:

-

Free Shipping

Express Shipping ServiceEstimated delivery time: 3-5 Working Days

- Quantity:

- Stock:32

- Weight:

- 12.2 KG

- Package:

Related Download Files

ANCEL ANJ400 GDI Piezo Fuel Injector Tester for Car Mortocycle Injector Cleaner Ultrasonic Cleaning Leack Test Diagnostic Tool

Ancel ANJ400 GDI Fuel Injector 4-cylinder Cleaner and Tester can clean and test standard injectors, EFI, FEI injectors, as well as GDI injectors such as for Mercedes Benz, BMW, Audi, Porsche, Ford, and other direct injection engines. It comes with multi voltages available for GDI injectors, which enables to adapt for different types of injector testing. The machine is the necessary and preferred equipment for the automotive serving and maintenance, research, and teaching training departments.Support for more cars and motorcycles. Can only be used to clean Gasoline fuel injectors. The cleaning fluid is 3M car injector cleaning fluid, and the test fluid is industrial alcohol.

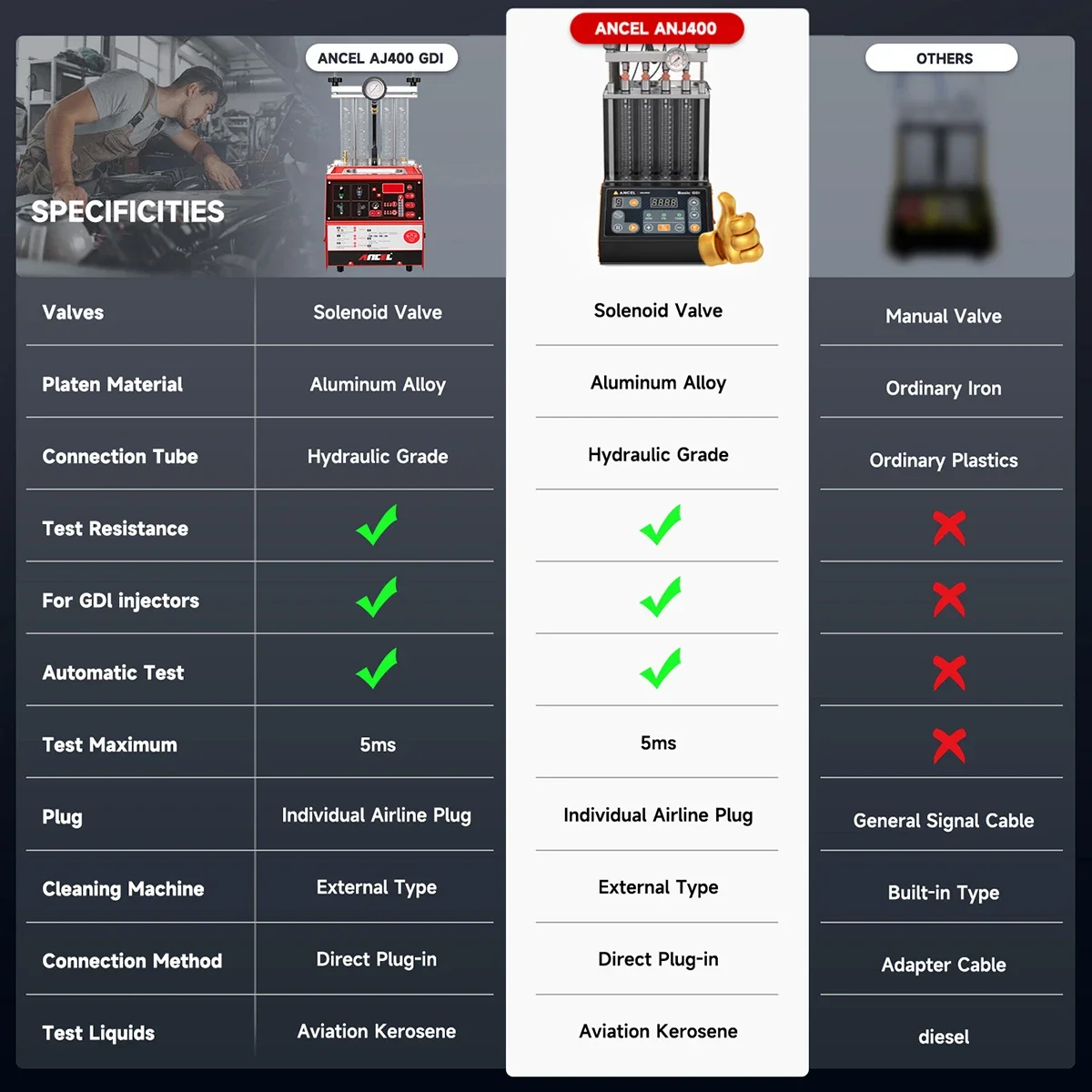

Compared with the Others Brand device on the market, what are the advantages of ANCEL ANJ400 GDI?

1.ANCEL ANJ400 GDI use solenoid valves, Others uses manual valves: the advantages of solenoid valves compared to manual valves include automatic control, fast response, precise control, energy saving and environmental protection, long life and safety and reliability.

2.ANCEL ANJ400 GDI upper pressure plate and the lower pressure plate are made of aluminum alloy, which has high manufacturing cost and light weight. Others uses iron material.

3.ANCEL ANJ400 GDI adopts hydraulic grade joint pipe, which has stronger pressure bearing capacity, corrosion resistance and wear resistance, and better sealing performance. Others uses ordinary joint pipes.

4.ANCEL ANJ400 GDI can test the resistance value of the fuel injector and display the value. Others do not have this function.

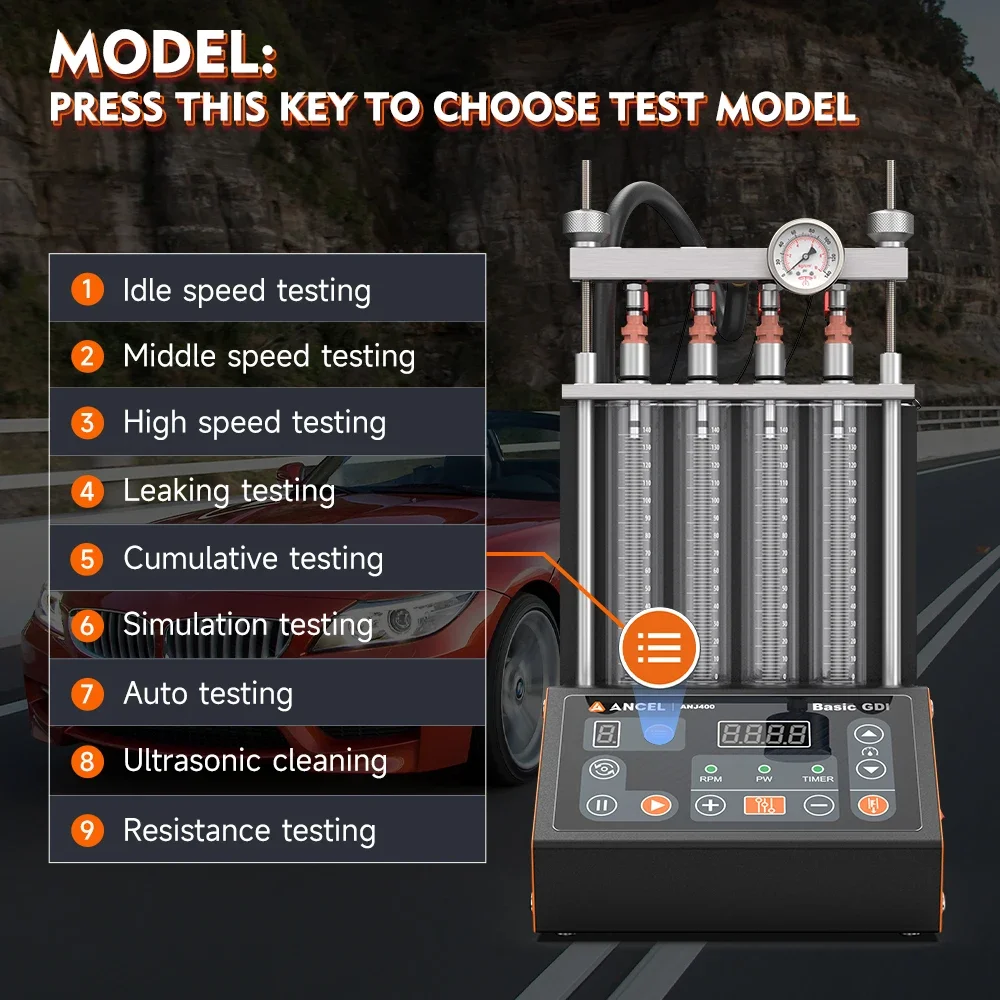

5.ANCEL ANJ400 GDI supports idle test, drip test, speed test...and automatic test, which concentrates all test functions in one mode.

6.ANCEL ANJ400 GDI Maximum no more than 5ms.

7.ANCEL ANJ400 GDI. You can set the output voltage, if you light up the GDI button, it is 70V, if you don't light up the button, it is 12V.

And more....

Main functions

* Ultrasonic cleaning

To clean injectors to remove the carbon deposition on them completely.

* Resistance test

To test the resistance of fuel injector.

*Uniformity / Sprayability test

To test the uniformity of injecting amount of each injector, and to monitor the spraying status of each injector

with the help of backlight.

* Leakage test

To test the sealing and dribbling conditions of injectors under system pressure.

* Injecting flow test

To check the injecting amount of the injector in 15 seconds of constant injection.

* Working modes test

To test injectors under different working conditions.

* On-Vehicle Cleaning

Coming with a variety of disassembly-free cleaning connectors, the device can be used to perform on-vehicle

cleaning and maintenance for various vehicle models.

* Low resistance injectors test function

Through the dedicated motherboard, it supports the full and long test of low resistant fuel injector such as 1

ohm.

* Multi items Setting

Set different parameters of the device, including the buzzer sound level, display brightness, and backlight

brightness.

* Version information

to check the software version information of the current device.

Main Features

*The special structure design makes the disassembly and assembly of the fuel separator easier and

greatly improves the work efficiency.

* With the resistance test of the injectors one by one, get to know the condition of the injectors.

* The ultrasonic cleaner is integrated on the machine, which makes the operation easier and more efficient.

* With the dedicated motherboard, it can support the full and long test of low resistant fuel injector such as

1 ohm.

*The unique fuel circuit depressurization technology can make the machine automatically depressurize in the

case of sudden shutdown, avoiding equipment damage or personal injury.

*The brightness of the screen and backlight, and the level of the buzzer can be manually set and saved.

* The product adopts fuel pressure adjustment and control technology by microcomputer, which can

ensurestable fuel pressure and wide adjustable range. It is applicable to vehicles equipped with a variety of

gasoline injection systems. Meanwhile, the automation of injectors’ cleaning and testing processes can be

realized.

* Thanks to the adoption of microcomputer automatic control and digital display technologies, the cleaning

and testing processes can be controlled automatically, and the parameters of the main status can be

monitored in realtime.

* Adopting humanization design can make the system pressure fast restored to the default values

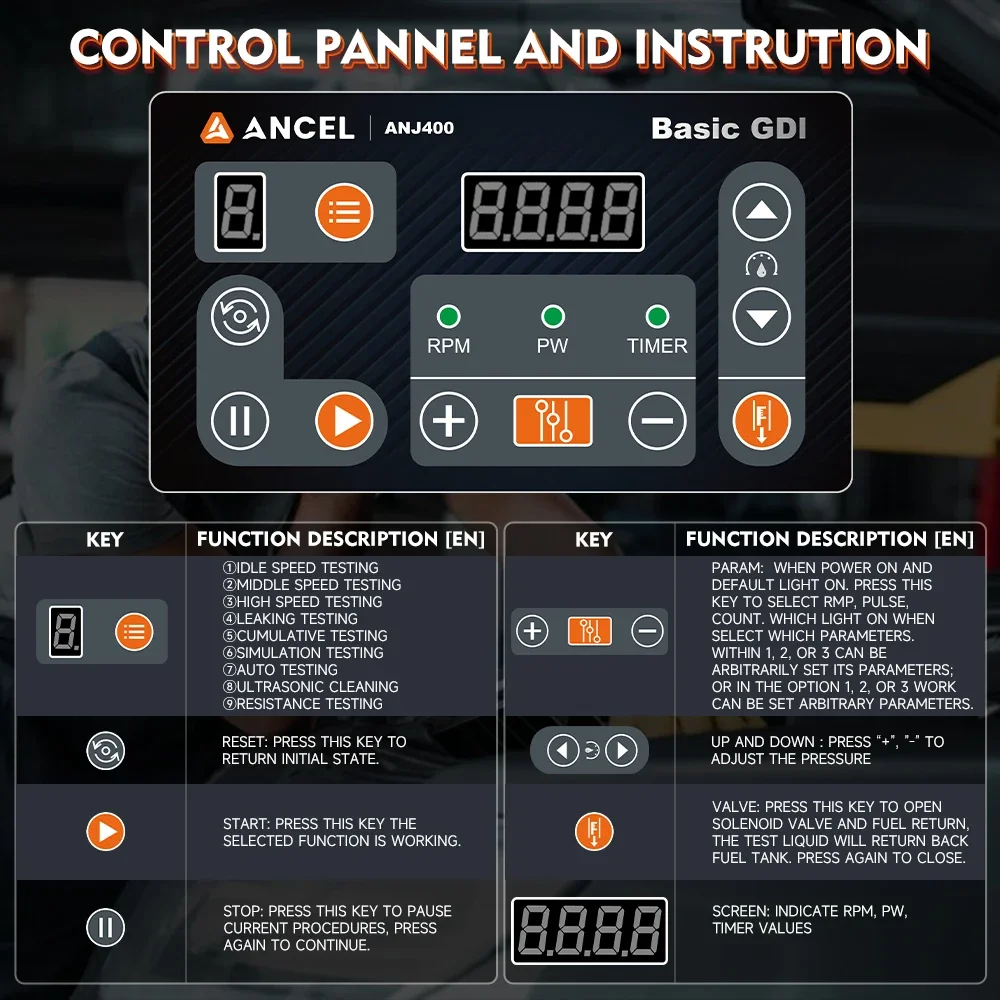

Resistance Test

1) Connect one end of the resistance measurement line to the interface on the right side of the device, and the other

end to the two electrodes of the fuel injector.

2) Start the machine, and press the key to modle 9.

3) If needed, measure several times to confirm the measured value.

4) After the measurement is completed, remove the fuel injector and the resistance measurement line

Ultrasonic Cleaning

Start the machine, and press the key to modle 8.Injector Cleaner takes advantage of the penetrability and

cavitation impact wave caused by ultrasonic wave traveling through the medium to provide powerful cleaning on

objects with complex shapes, cavities and pores, so that the stubborn carbon deposits can be removed from the injectors.

Uniformity/Sprayability Test

Uniformity test is to find out the difference of the injectors injecting at the same working condition. This test can

indicate the comprehensive influences on the injector caused by electrical nature, bore variation and clogging. Spray ability testis to inspect the spraying performance by observing the injectors

Leakage Test

Leakage test is to inspect the sealing conditions of the injector needle valve under system pressure and to find out if the injector is dribbling

Injecting Flow Test

Injecting flow testis to check if the injecting flow in 15 seconds meets the specifications for injecting amount. The deviation reflects the wear or clogging in the injector, instead of electrical parameter variation

Working modes test

Working modes test contains three working status simulation tests(Acceleration, Deceleration, Acceleration+

Deceleration test). This function can test more comprehensive performance of injectors by simulating the various engine working conditions.

On-Vehicle Cleaning

After the motorcycle engine has been in operation for a period of time, its fuel flow may be blocked or become un- smooth owing to buildup of dust and impurities in fuel channel. In addition, the carbon deposits and gum made by combustion can easily adhere to the injectors, inlet and outlet ports, inlet and outlet hoses, throttle and combustion chamber. So the fuel supply system, combustion chamber and injector of the engine must be cleaned on a timely basis. Combustion Chamber cleaning is a solution that can save your time and labor

Digital Display and Smart Contorl

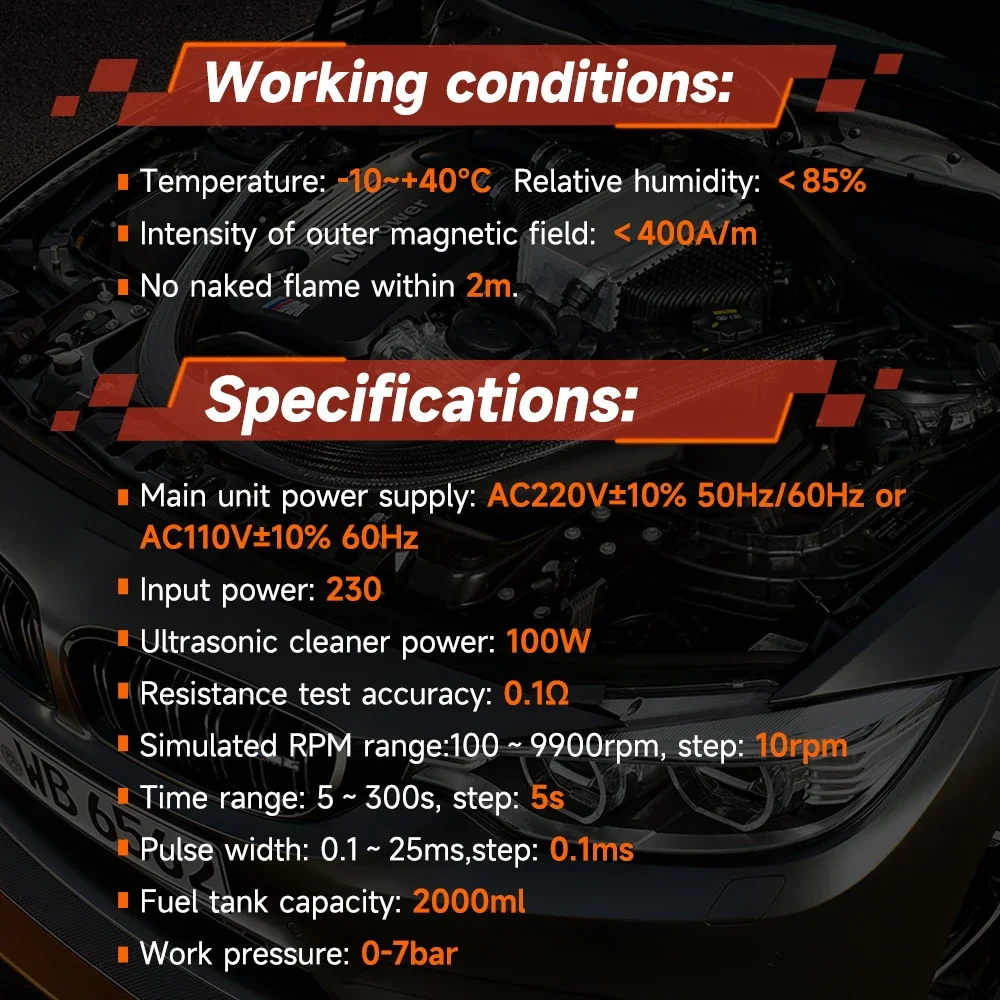

Working conditions:

Temperature: -10~+40℃ Relative humidity: <85% Intensity of outer magnetic field: <400A/m

No naked flame within 2m.

Specifications:

Main unit power supply: AC220V±10%,50Hz/60Hz or AC110V±10%,60Hz

Input power: 230W

Ultrasonic cleaner power: 100W

Resistance test accuracy: 0.1Ω

Simulated RPM range: 100~9900rpm, step: 10rpm

Time range: 5~300s, step: 5s

Pulse width: 0.1~25ms, step: 0.1ms

Fuel tank capacity: 2000ml

Work pressure: 0-7bar

Package Components

Fuel Injector Tester & Cleaner *1

Adjusted screw *2

Fuel feed funne*1

Fuel pipe *1

Φ11 underlay of injector*4

Injector plate Φ14 flat plate*4

Pulse line of injector(4 injectors)*1

Power line*1

Special line*4

Top feed injector rail* 1

Sealed ring of connectors(7.52x3.53) *10

R1/4blank plug *3

European standard connectors Φ13.6 *4

Standard connectors Φ10.6 *4

Connector of Benz mechanical injector (M12x1.5) *4

Conector de inyector Φ12.5 (GDI Conector) *4

Conector de inyector Φ9.8 (GDI Conector) *4

Conector de inyector ΦM18 (GDI Conector) *4

Tool box *1

0 Stars of 5,0 Reviews.

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

Share your thoughts with other customers.

Write a reviewYou may also like

-

Launch CNC601A Automotive fuel injector tester&cleaner 220V/110V with English panel CNC-602A for 6 or 4 cylinders Gasonline car

$879.002% off

-

Launch TLT235SC Economical Floorplate Two Post Car Lift

$1289.005% off

-

Launch TLT840WA 4 Tons Double Scissor Lift Suitable For Small Passenger Cars and Light Trucks

$4099.002% off

-

Tektino INJ-8B 8 Cylinders Fuel Injector Cleaning Machine For Gasoline Engines for Automotive Repair Clean And Test

$989.007% off

-

AUTOOL CT500 GDI EFI FEI Fuel Injector Cleaner & Tester Machine 6 Cylinders Fuel Injector Cleaner Tester for Car & Motorcycle

$659.006% off

-

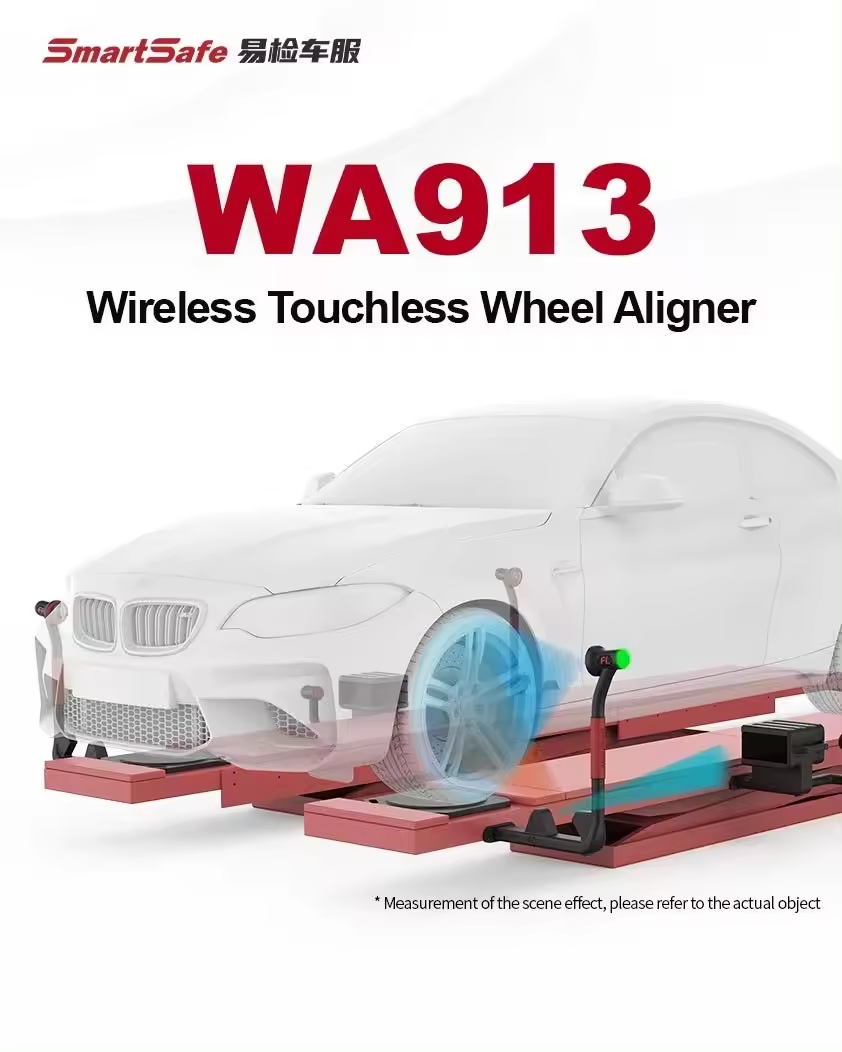

2025 3D Wheel Alignment Machine WA913 Fully Automatic Car Four Wheel Aligner Wireless Touchless Wheel Aligner Auto Equipment

$13399.001% off

-

Tel

+86-19892834301 -

WhatsApp