- WhatsApp:+86-19892834301

- Email: automantool@hotmail.com

- Skype:autoobdtop

ANCEL BR2000 Car Gearbox Brake Fluid Bleeder Vaccum Oil Exchange Machine Built-in Pressure Pump Pressure Gauge

0 out of 50 global ratings

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

ratings| answered questions

0 global ratings

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

Fast Shipping & No Tax

US Check: Ship from US

UK Check: Ship from UK

EU Check: Ship from Czech

Looking for help? Please contact Whatsapp: +86-19892834301

- Shipping:

-

Free Shipping

Express Shipping ServiceEstimated delivery time: 3-5 Working Days

- Quantity:

- Stock:32

- Weight:

- 2.8 KG

- Package:

Related Download Files

ANCEL BR2000 Car Gearbox Brake Fluid Bleeder Vaccum Oil Exchange Machine Built-in Pressure Pump Pressure Gauge

Ancel BR2000 Automotive Brake Fluid Bleeder is a brake fluid exchanger equipment. The physical principle is to suck the brake fluid from the new fluid storage tank through a pump, and continuously pump it into the automobile brake fluid container at a specified pressure. Compared with the traditional compressing way to exchange brake fluid, this pulsating brake fluid exchanger can effectively avoid the generation of air bubbles during the filling process, thereby optimizing or avoiding the artificial exhaust process.

Ancel BR2000 Features

1. [One-person Operation&Time Efficient]: Ancel BR2000 Automotive Brake Fluid Bleeder can be operated by one person, four wheels oil can be exchanged together. Four pumps exchange oil simultaneously can save time and labor.

2. [Electric Brake Fluid Exchange]: No need to connect an air compressor. Ancel BR2000 Automotive Brake Fluid Bleeder comes with a built-in working pressure pump. Brake fluid can be exchanged by simply connecting 110V/220V power supply.

3. [Smart adjustment panel design&Pressure Gauge]: One-press fluid exchange. Complete the oil exchange within one minute, conveniently and quickly. Pressure and frequency can be freely adjusted. Equipped with a pressure gauge to observe the fluid exchange pressure value.

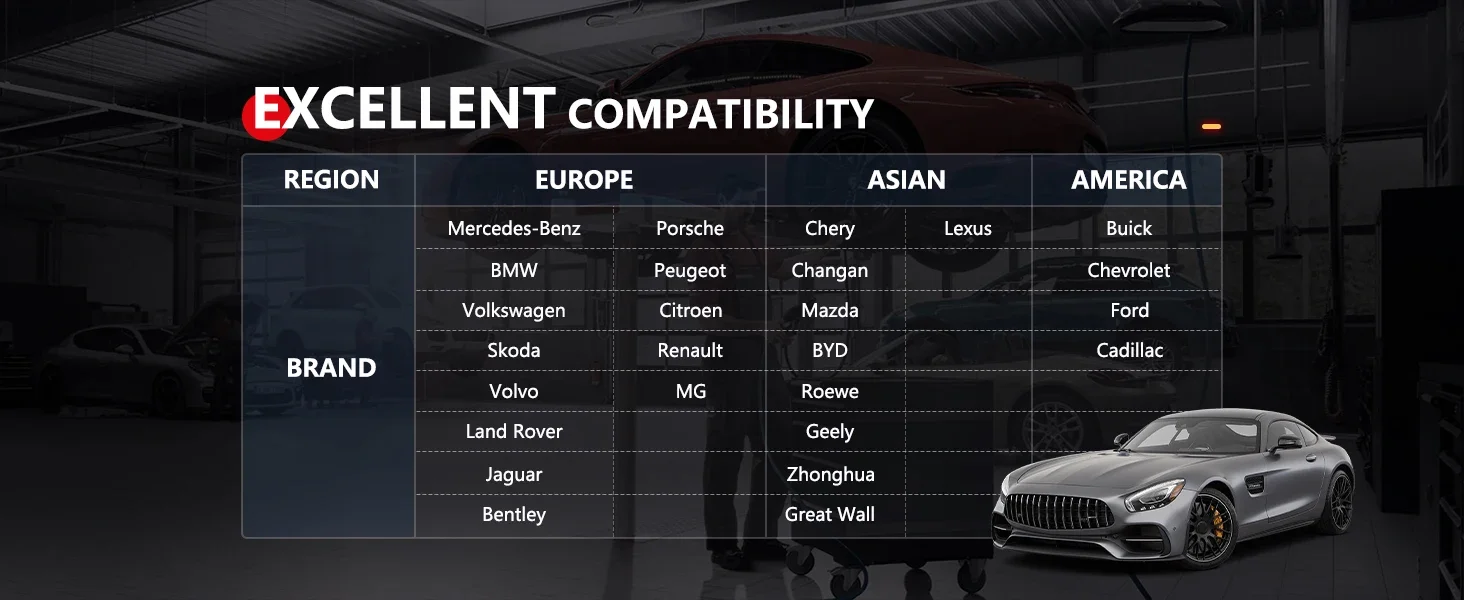

4. [Wide range of applicable models]: Come with a variety of adapters. Suitable for European, American, and Asian models.

5. [Three Years Warranty, Lifetime Maintenance]: For damage caused by non-human factors,Ancel promises to resend parts for free within 3 years. For any needs, you are warmly welcomed to contact us and we will get back to you ASAP within 24 hours.

Operating Principle:

1. Brake fluid is taken from its container by a pump operating at up to 3.0 bar pressure and is continuously. pumped into the brake fluid reservoir. The individual wheel brake cylinders can then bedrained of their used brake fluid until the new brake fluid comes through.

2. You thus avoid the regular emptying and filling operations, in contrast to conventionalsystems and also. avoid any resulting water absorption in the brake fluid.

3. The pump used to fill the brake fluid reservoir is equipped with pressure monitoring. Should it not be. possible to build pressure or should the pump pull in air, the pump switches itself off automatically.

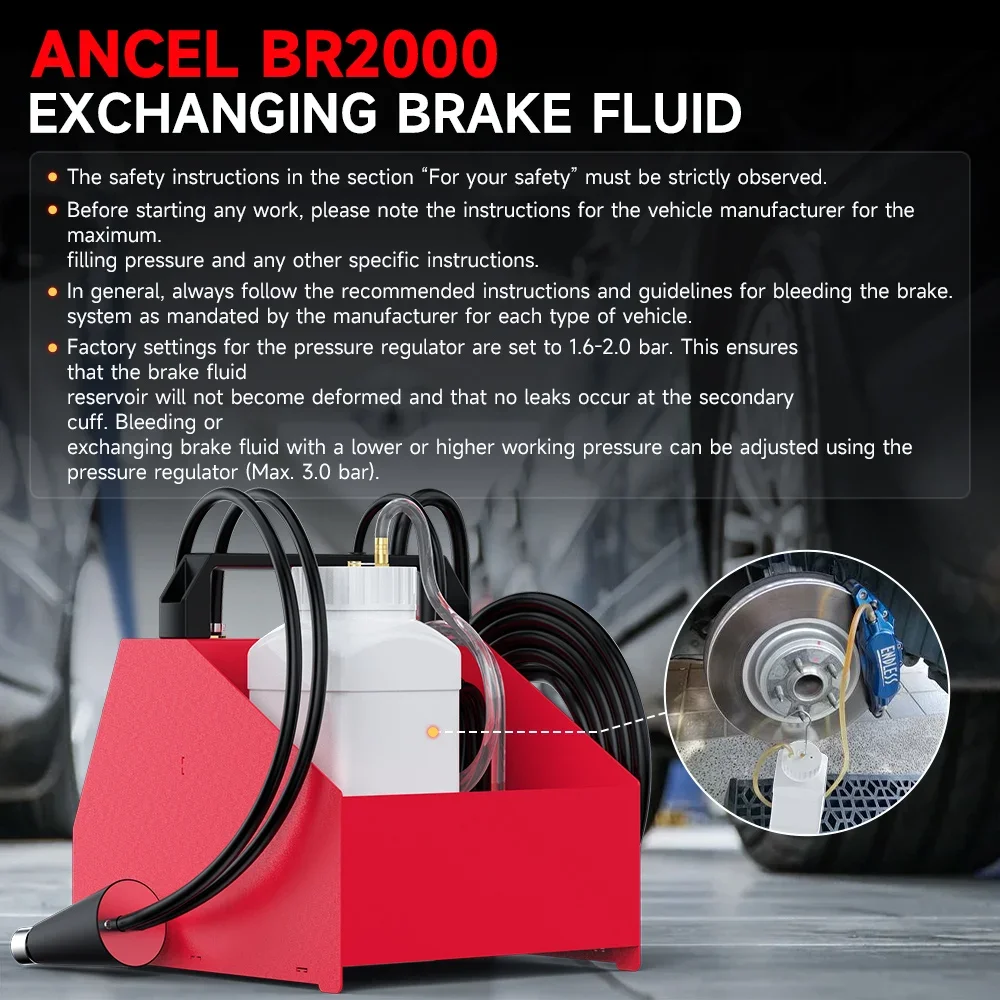

ANCEL BR2000 EXCHANGING BRAKE FLUID

1. The safety instructions in the section"For your safety"must be strictly observed.

2. Before starting any work, please note the instructions for the vehicle manufacturer for the maximum. filling pressure and any other specific instructions.

3. In general, always follow the recommended instructions and guidelines for bleeding the brake. system as mandated by the manufacturer for each type of vehicle.

4. Factory settings for the pressure regulator are set to 1.6-2.0 bar. This ensuresthat the brake fluid reservoir will not become deformed and that no leaks occur at the secondary cuff. Bleeding or exchanging brake fluid with a lower or higher working pressure can be adjusted using thepressure regulator (Max.3.0 bar).

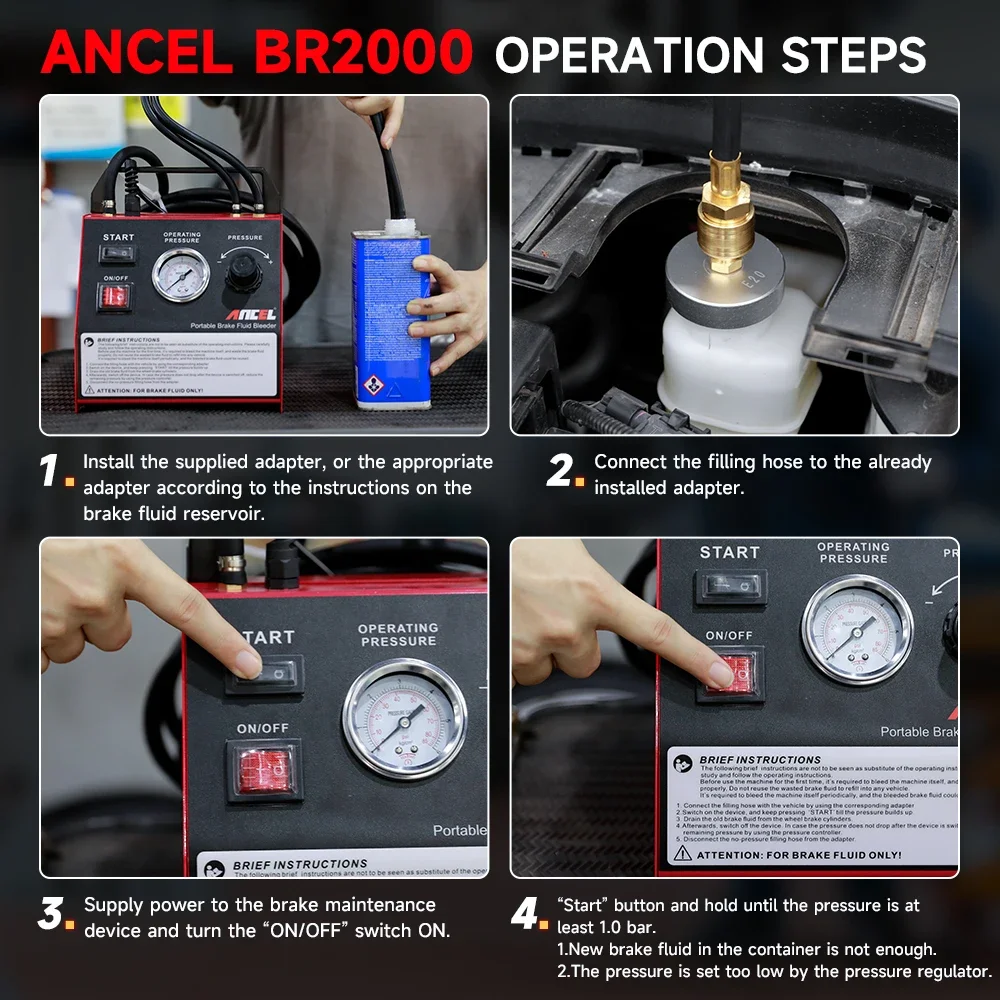

Operation Steps:

Step 1: Put the suction hose in the brake fluid bottle;

Step 2: Connect the adapter and the oil- drain pipeline;

Step 3: Turn on the equipment and adjust the pressure;

Step 4: Connect the fluid recycling bottle to the brake fluid dispense bump.

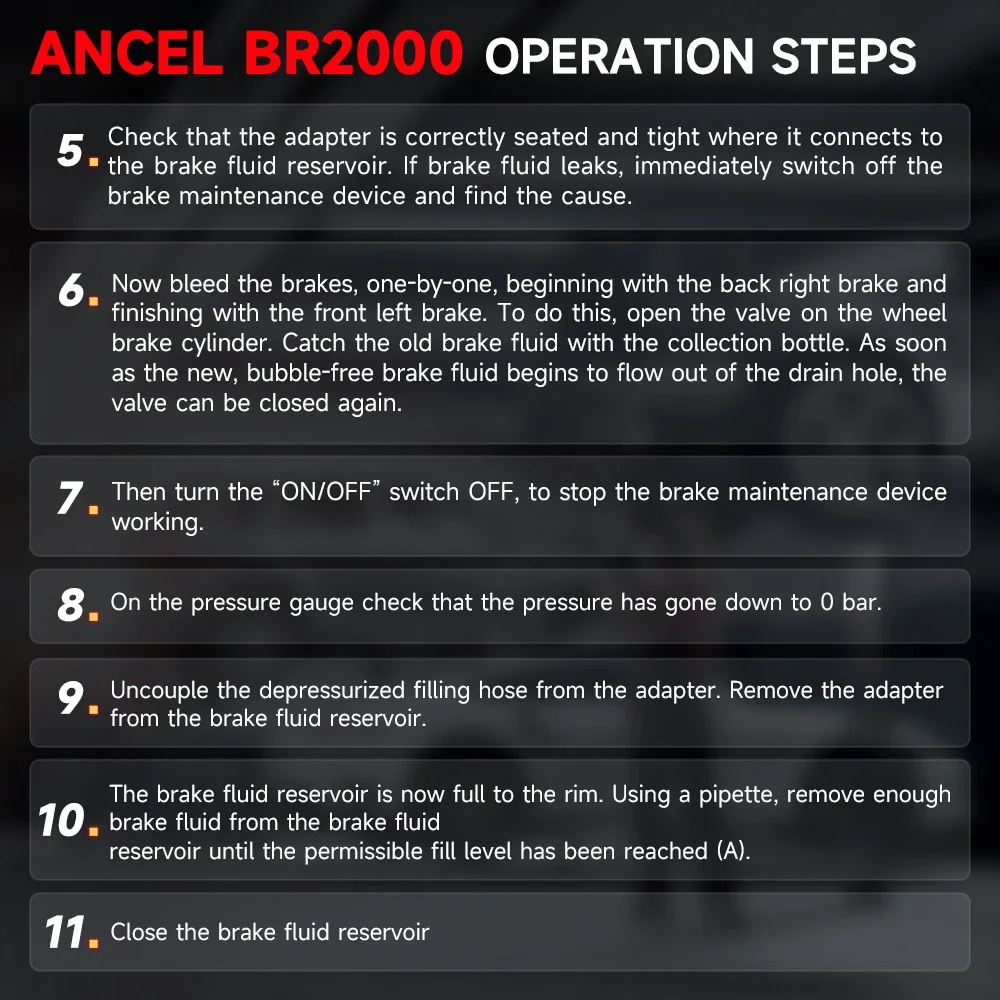

Step 5: Check that the adapter is correctly seated and tight where it connects to the brake fluid reservoir. If brake fluid leaks,immediately switch off the brake maintenance device and find the cause.

Step 6: Now bleed the brakes, one-by-one, beginning with the back right brake and finishing with the front left brake. To do this, open the valve on the wheel brake cylinder. Catch the old brake fluid with the collection bottle. As soon as the new, bubble-free brake fluid begins to flow out of the drain hole, the valve can be closed again.

Step 7: Then turn the“ON/OFF”switch OFF, to stop the brake maintenance device working.

Step 8: On the pressure gauge check that the pressure has gone down to 0 bar.

Step 9: Uncouple the depressurized filling hose from the adapter. Remove the adapter from the brake fluid reservoir.

Step 10: The brake fluid reservoir is now full to the rim. Using a pipette, remove enough

brake fluid from the brake fluid reservoir until the permissible fill level has been reached (A).

Step 11: Close the brake fluid reservoir

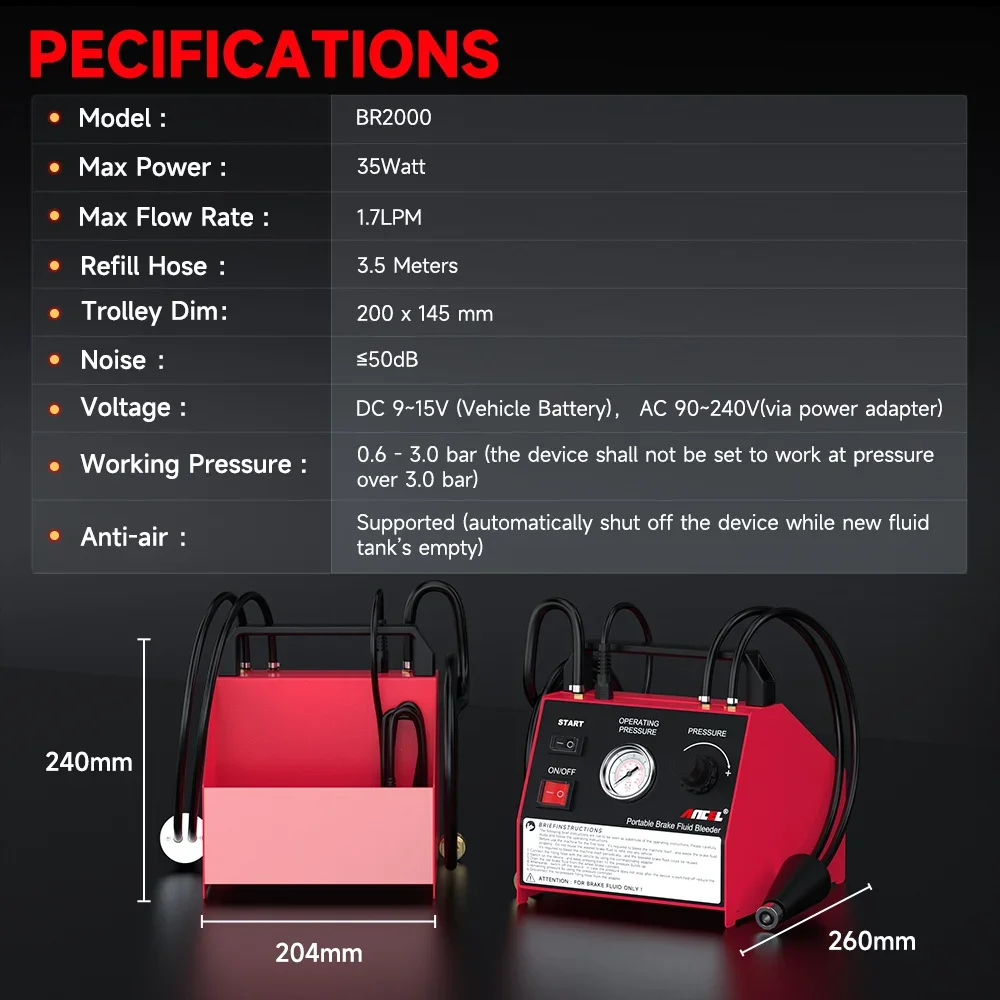

Parameters:

Voltage: DC 9~15V , AC 90~240V

Maximum power: 25W;

Maximum flow: 1.7 liters/min;

Working pressure: 0.6-3.0 bar;

Oil shortage protection: support;

Filling hose length: 3.5m;

Noise: ≦56dB;

Host size: 260×204×240 mm

Packing List:

Notice:

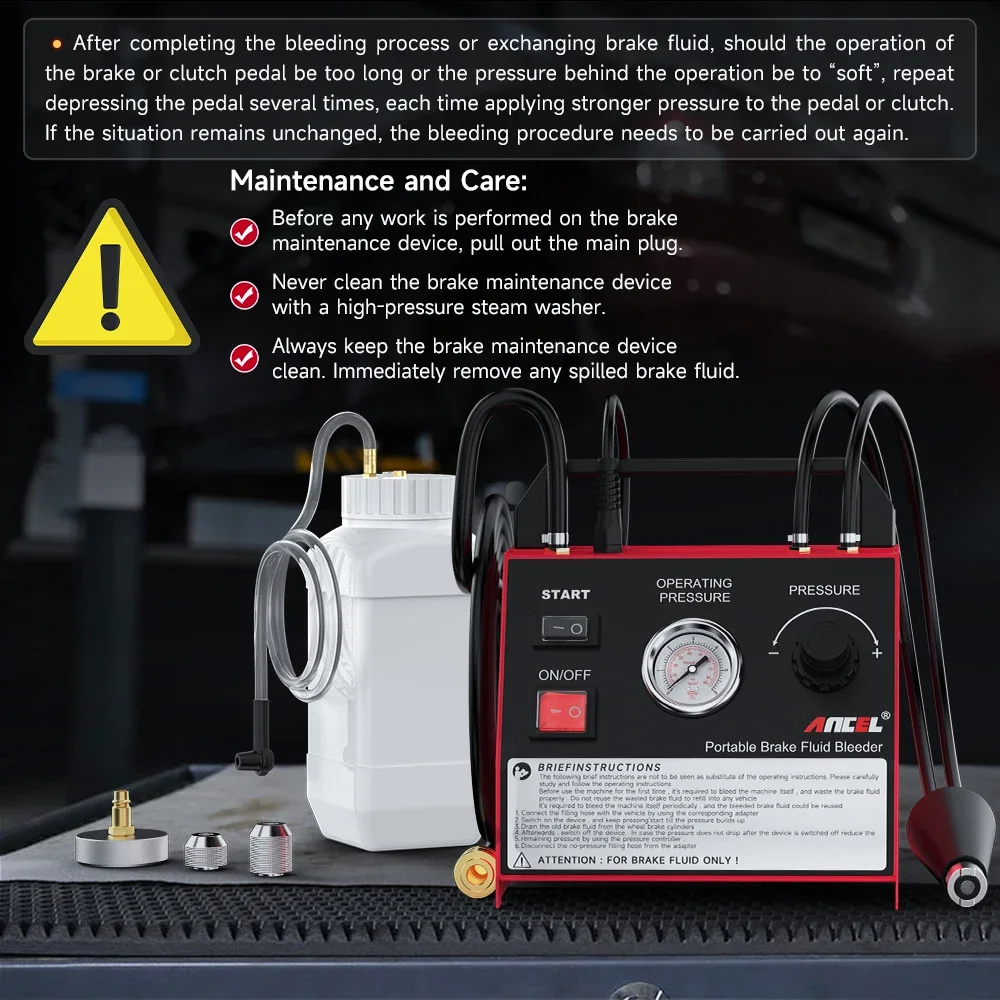

After completing the bleeding process or exchanging brake fluid, should the operation of the brake or clutch pedal be too long or the pressure behind the operation be to "soft ", repeat depressing the pedal several times, each time applying stronger pressure to the pedal or clutch. lf the situation remains unchanged, the bleeding procedure needs to be carried out again.

Maintenance and Care:

1. Before any work is performed on the brake maintenance device, pull out the main plug.

2. Never clean the brake maintenance device with a high-pressure steam washer.

3. Always keep the brake maintenance device clean. Immediately remove any spilled brake fluid.

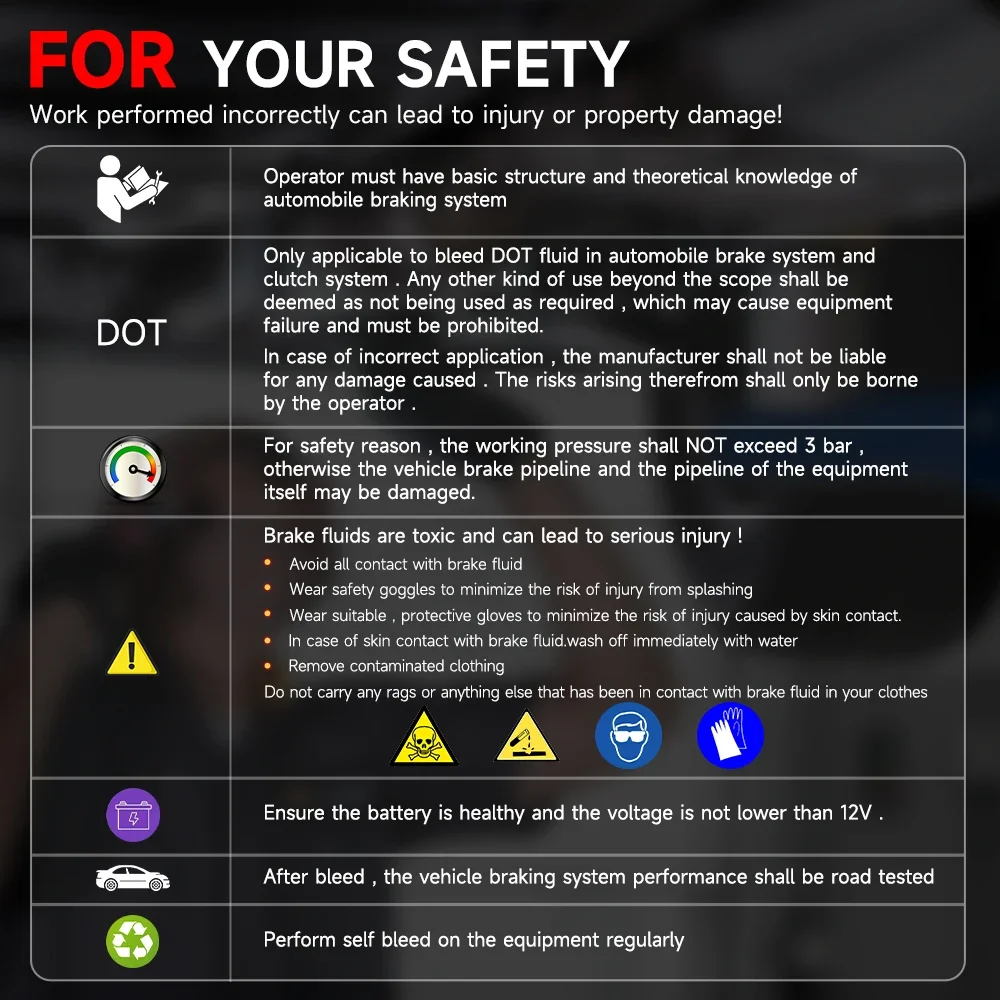

FOR YOUR SAFETY

Work performed incorrectly can lead to injury or property damage!

0 Stars of 5,0 Reviews.

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

Share your thoughts with other customers.

Write a reviewYou may also like

-

ANCEL FD500 OBD2 Scanner for Ford Lincoln Mercury All Systems Code Reader with Engine ABS SRS Transmission 4WD Diagnostics Scan

$59.0014% off

-

Ancel PB50 Automotive Circuit Tester 12V 24V Power Circuit Probe Kit Electrical Diagnostic Tool Digital Voltage Short Finder

$45.008% off

-

ANCEL MR500 Intelligent Marine Scanner Tablet Fit For Suzuki Watercraft & Outboard Fault Diagnostic Tool For Yamaha For Suzuki

$619.003% off

-

ANCEL BD310 OBD2 Scanner Scan Professional 3 in 1 On-Board Computer For Car Digital Meter OBD 2 Car Diagnostic Tools Free Update

$65.006% off

-

ANCEL X6 HD Heavy Duty Truck Diagnostic Scanner For Isuzu ABS Airbag DPF OBD2 Scanner For Trucks Diesel OBD Diagnostic Scan Tool

$559.007% off

-

Ancel HD3400 OBD2 Scanner Full System Diagnostic Tool DPF Regeneration For Heavy Duty Diesel Truck Scan Tools

$399.0020% off

-

Tel

+86-19892834301 -

WhatsApp