- WhatsApp:+86-19892834301

- Email: automantool@hotmail.com

- Skype:autoobdtop

LAUNCH CNC 603C 220V 300W Injector Cleaner & Tester CNC 603C Fuel Injector Tester Cleaning Machine Test Bench Equipment tools for garage

0 out of 50 global ratings

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

ratings| answered questions

0 global ratings

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

Fast Shipping & No Tax

US Check: Ship from US

UK Check: Ship from UK

EU Check: Ship from Czech

Looking for help? Please contact Whatsapp: +86-19892834301

- Shipping:

-

Free Shipping

Express Shipping ServiceEstimated delivery time: 3-5 Working Days

- Quantity:

- Stock:29

- Weight:

- 16 KG

- Package:

Related Download Files

1. Functions and

Features

Main

Functions

Uniformity / Sprayability

test: to detect the uniformity of the fuel injection

quantity of each injector and monitor the spray status of injectors thoroughly

and carefully by using the backlight, and to backflush

injectors.

Leakage test: to test the leakage

and dribbling conditions of injectors under system

pressure.

Injecting flow test: to detect the amount

of fuel injected normally by injectors in 15

seconds.

Auto test: under specific working

conditions and parameters, the precise simulation of test of injectors under

various working conditions

Ultrasonic cleaning: to perform ultrasonic

cleaning on multiple injectors at the same time, removing carbon deposits on

injectors completely.

On-Vehicle Cleaning: Coming with a variety

of disassembly-free cleaning connectors, the device can

be

used to perform on-vehicle cleaning and maintenance

for various vehicle models.

Language selection: the system supports

multiple languages and users can choose the appropriate language according to

their needs.

Version information: to check the software

version information of the current device.

Main Features

*Adopting ultrasonic

cleaning technology, CNC-603A Injector Cleaner & Tester presents a strong

cleaning ability;

*The product also

adopts fuel pressure adjustment and control technology by microcomputer, which

can ensure stable fuel pressure and wide adjustable range. It is applicable to

vehicles equipped with a variety of gasoline injection systems. Meanwhile, the

automation of injectors' cleaning and testing processes can be

realized.

*Thanks to the adoption

of microcomputer automatic control and digital display technologies, the

cleaning

and testing processes can be controlled automatically

and the parameters of the main status can be monitored in real

time.

*Automatic fuel drain

during a certain test can be realized via a routine, owing to the adoption of

automatic

fuel drain control technology. Start or [stop] fuel

drainage via the [Drain] button on the control panel in running or stop

state

1. Cleaning and Testing

Sequences

It is recommended to carry out the complete cleaning

and testing procedures in the following order.

*Ultrasonic

cleaning;

*Uniformity / Sprayability

test;

*Leakage test;

*Injecting flow

test;

*Auto. test.

Select the

corresponding parameter according to different test items and set it. See "V.

Operation Processes" for

details.

2. Cleanup after

Operation

After the end of cleaning and testing, a cleanup

should be done, which includes:

*Press [Drain] button

on the control panel to drain test solution to a fuel

container.

*Switch off the power switch and unplug the power

plug.

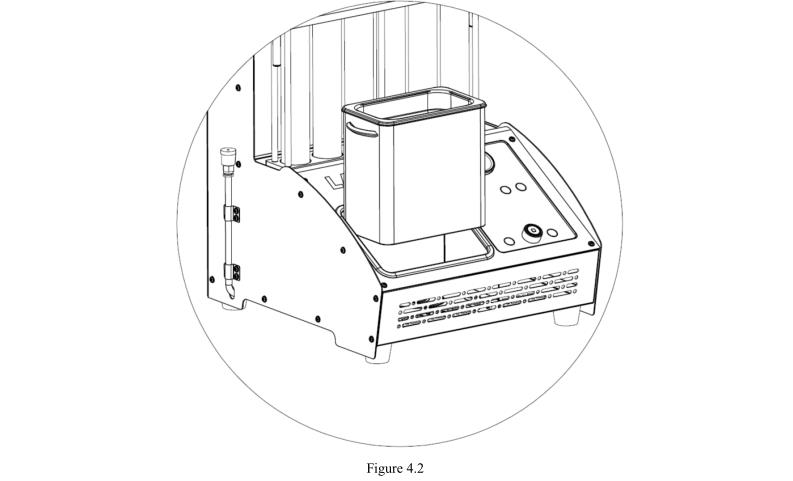

*Take out the ultrasonic cleaning pool and pouring

out all cleaning fluid completely shown in Figure 4.2, and wipe the

ultrasonic cleaning unit with a soft dry cloth.

*Wipe the table top of

the machine with a soft dry cloth.

*To avoid

volatilization, all the test solution in the fuel tank should be discharged. If

it can be used again, store it in a safe place. If it is dirty and cannot be used

any more, dispose it according to relevant regulations.

3. Specifications: Working

Environment:

Power: AC110V-127V,50Hz/60Hz 3Amax

AC220V-230V,50Hz/60Hz 1.5Amax

Mechanical Power:

300W

Ultrasonic Cleaning

Power: 100W

Speed Range for Simulation

Test: 10~9990rpm

(step: 10rpm)

Environment

Temperature: 0ºC~+45ºC

Relative Humidity:

<85%

Strength of External Magnetic

Field: <400A/m

Open fires is strictly prohibited within

2m.

Timing Range:

1~9999s

Pulse Width Range:

0.5~25ms (step: 0.1ms)

Operating Volume: 3000ml

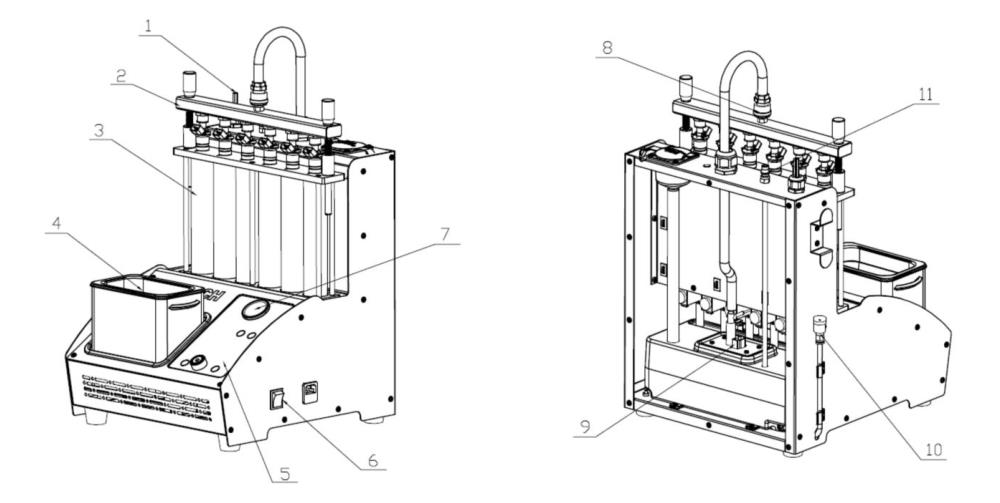

1- Pulse line; 2-Fuel

distributor assembly; 3-Observation window tube; 4-Ultrasonic

cleaner;

5-Control panel; 6-Power switch; 7-Fuel pressure gauge; 8-Quick

Connector ; 9-Fuel pump;

10-Fuel drainage pipe; 11-Automatic cleaning oil

return port

4. Language

Selection

To adapt to the needs of different countries, multiple

languages are available. Users can choose the appropriate

language according

to their needs.

Method and

Steps:

1) Move the cursor to the language selection icon on the

main interface and press the knob to enter the

language selection interface,

as shown in Figure 5.16.

2) Turn the knob to select the corresponding

language, as shown in Figure 5.17. Press the knob and the

system will

automatically change the language and exit the language selection interface

automatically.

There are English, Japanese, Russian, Korean, French,

Portuguese, Italian, Chinese to choose from.

0 Stars of 5,0 Reviews.

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

Share your thoughts with other customers.

Write a reviewYou may also like

-

AUTOOL CT400 GDI Fuel Injector Cleaner & Tester Machine 6 Cylinders Fuel Injector Cleaner Tester for Car & Motorcycle 110V 220V

$569.005% off

-

AUTOOL CT160 220V/110V 4-Cylinders Car Fuel Injector Flushing Nozzles Fuel Injector Tester Ultrasound Heating Cleaning Injectors Motorcycle

$299.006% off

-

Launch X-431 ADAS HD Professional ADAS Calibration Tool For Commercial Vehicles and Heavy Trucks

$7499.001% off

-

AUTOOL CT500 GDI EFI FEI Fuel Injector Cleaner & Tester Machine 6 Cylinders Fuel Injector Cleaner Tester for Car & Motorcycle

$659.006% off

-

AUTOOL CT150 Ultrasonic Auto FUEL Injector Cleaner Tester 220V/110V Upgrade Version of CT200

$289.006% off

-

Tel

+86-19892834301 -

WhatsApp