- WhatsApp:+86-19892834301

- Email: automantool@hotmail.com

- Skype:autoobdtop

AUTOOL CT180 Intelligent Upgrade Fuel Injector Tester Cleaning Machine Injector Ultrasonic Cleaner 4-Cylinders 110V 220V for GDI

0 out of 50 global ratings

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

ratings| answered questions

0 global ratings

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

Fast Shipping & No Tax

US Check: Ship from US

UK Check: Ship from UK

EU Check: Ship from Czech

Looking for help? Please contact Whatsapp: +86-19892834301

- Shipping:

-

Free Shipping

Express Shipping ServiceEstimated delivery time: 3-5 Working Days

- Quantity:

- Stock:35

- Weight:

- 9 KG

- Package:

Related Download Files

AUTOOL CT180 Intelligent Upgrade

Fuel Injector Tester Cleaning Machine Injector Ultrasonic Cleaner 4-Cylinders

110V 220V for GDI

Description:

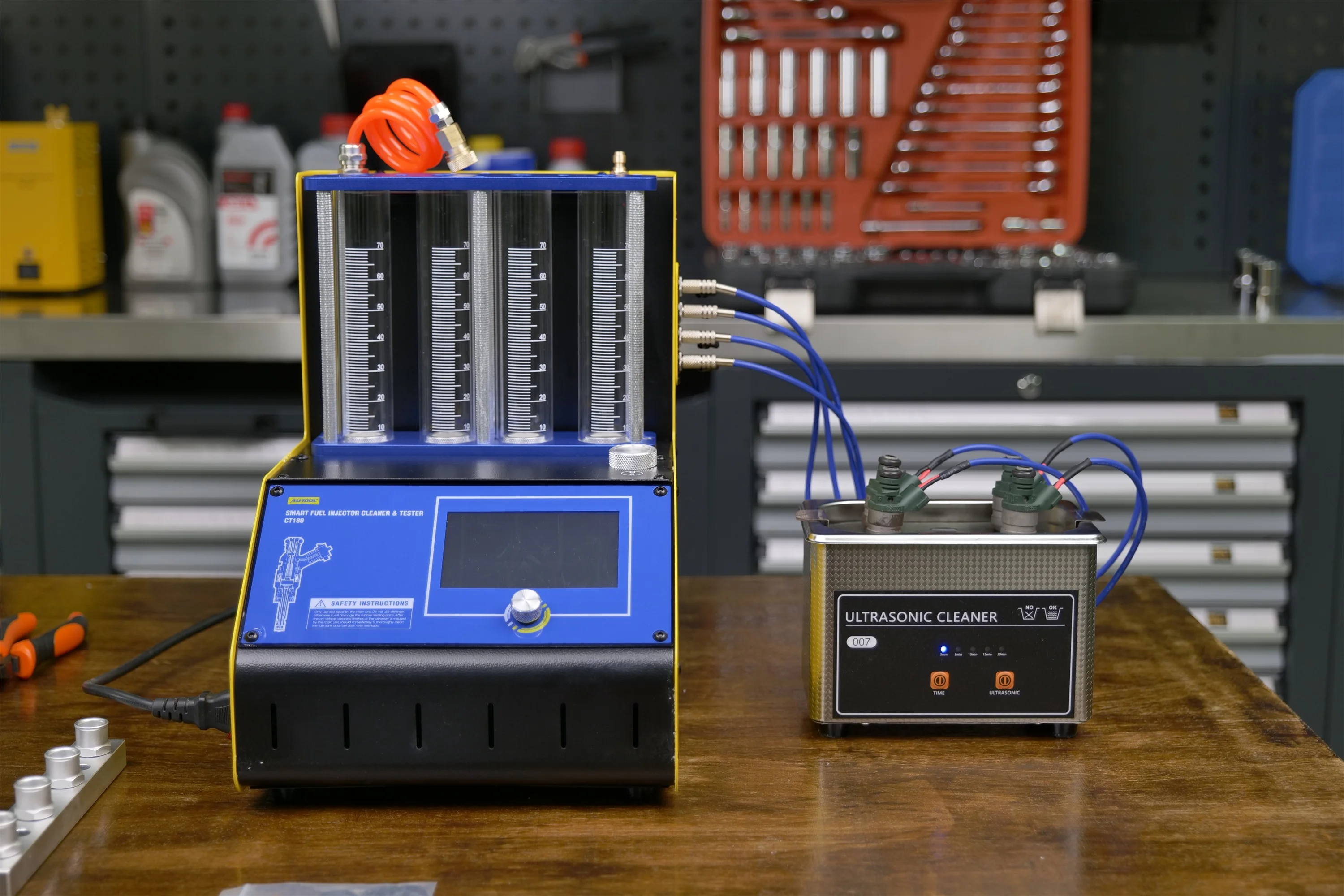

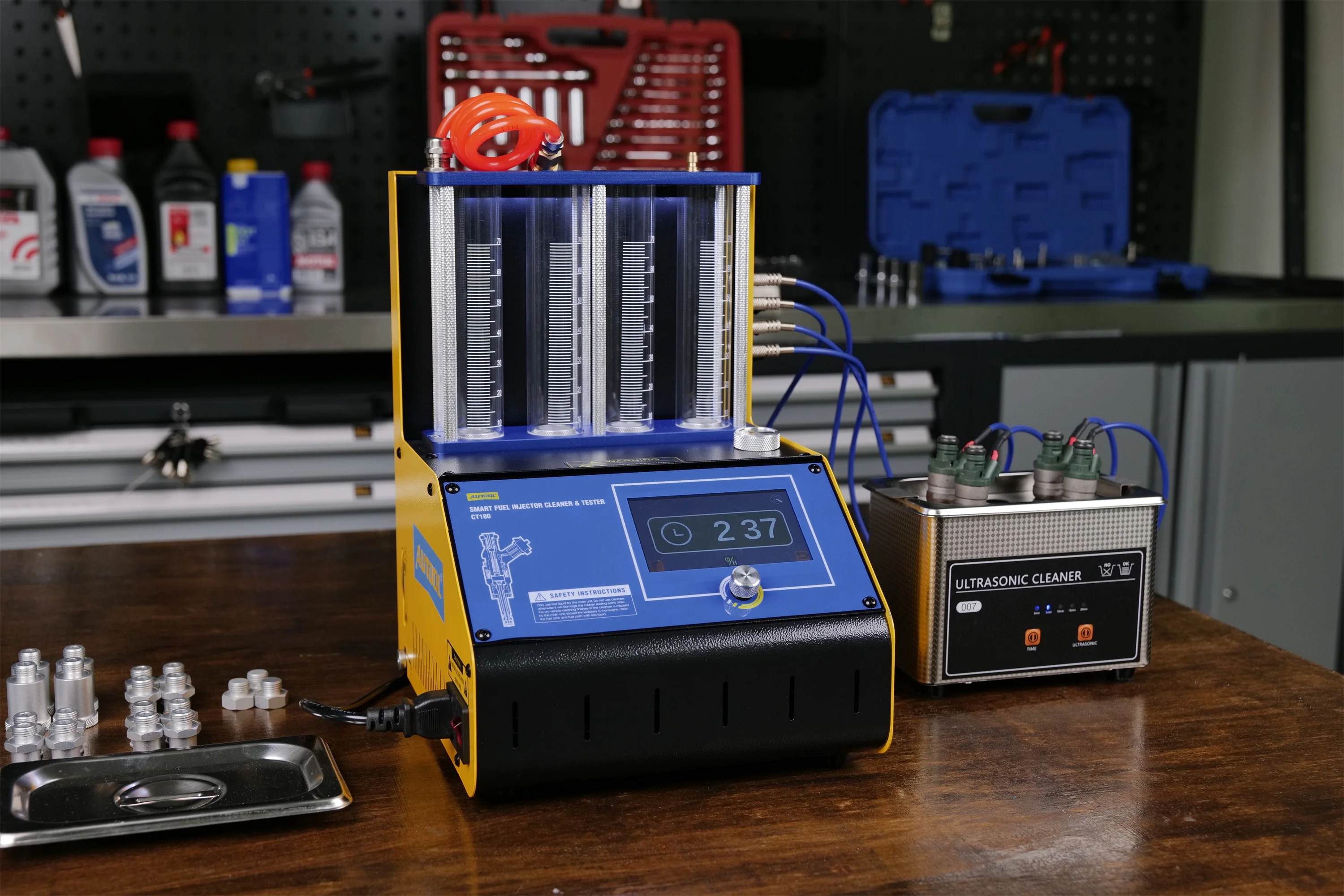

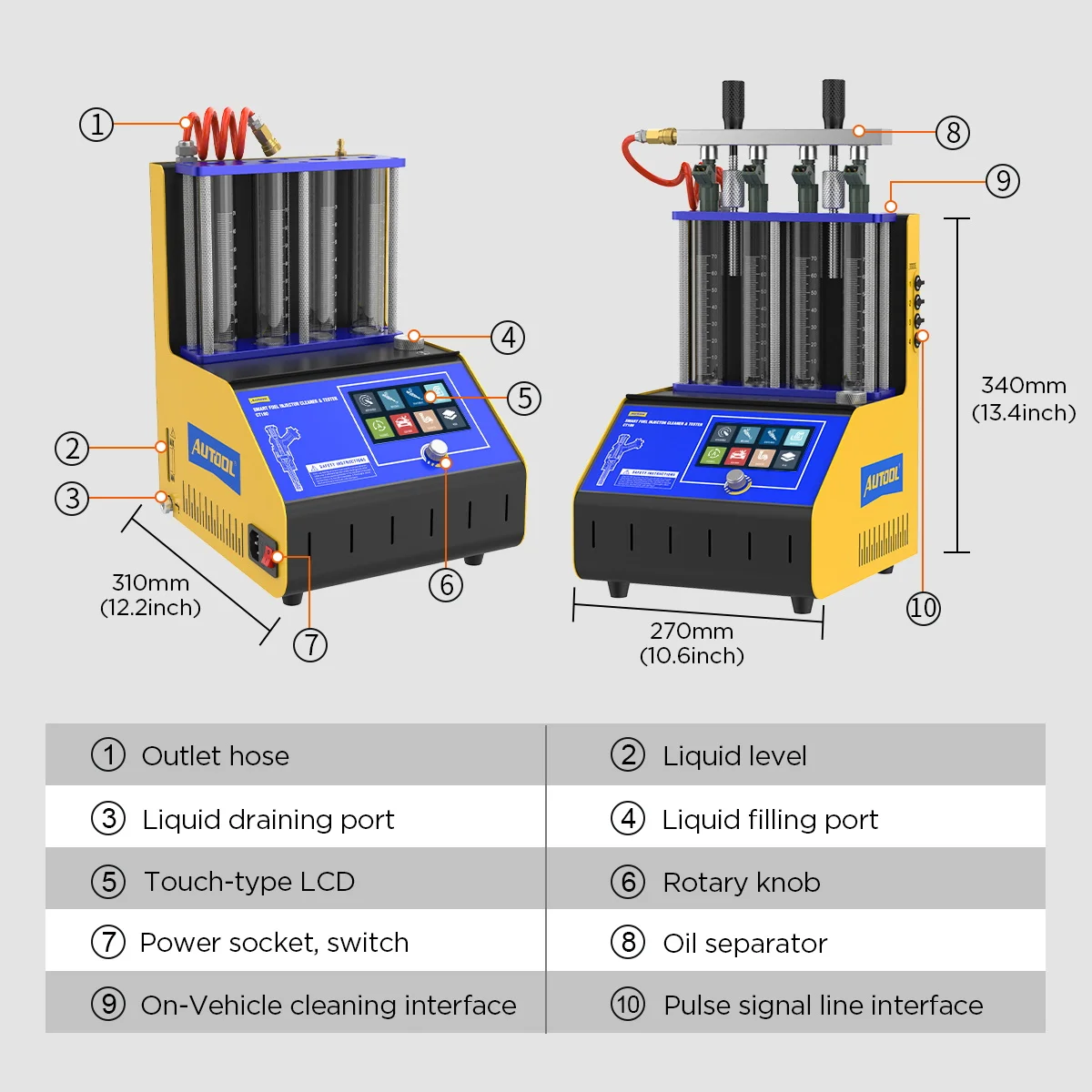

AUTOOL CT180 is an intelligent injector cleaning & testing equipment with intelligent control. The whole process can be operated by the touch screen or rotary knob to complete. Equipped with an ultrasonic cleaning tank, AUTOOL CT180 Fuel injector cleaner and Tester can generate an oscillating signal to the injectors to remove the stubborn carbon deposits from the injectors. It is possible to test injectors under different conditions, such as Sprayability test, Leakage test, Injecting flow test, etc. A comprehensive and powerful injector cleaner and tester machine most auto technicians always crave for.Support for more cars and motorcycles.Can only be used to clean diesel fuel injectors.The cleaning fluid is 3M car injector cleaning fluid, and the test fluid is industrial alcohol.Its working voltage range is 110-230V.

Support For 99% Cars & Motorcycles

Support for Audi,for Australia Ford,for Benz,for BMW,for Brilliance,for Chevrolet,for Chevy,for Chrysler,for Citroen,for Dacia,for Dadi,for Daewo,for Daihatsu,for Demo,for Fiat,for Ford,for GM,for Holden,for Honda,for Hyundai,for Isuzu,for Jaguar,for Kia,for Lancia,for Land Rover,for Mahindra,for Maruti,for Mazda,for Mitsubish,for Nissan,for Opel,for Peugeot,for Porsche,for Renault,for Romeo,for Rover,for Saab,for Seat,for Skoda,for Smart,for Subaru,for Suzuki,for Tata,for Toyota,for Volvo,for VW,for Yamaha.

CT180 Car Fuel Injector Tester Cleaner Features:

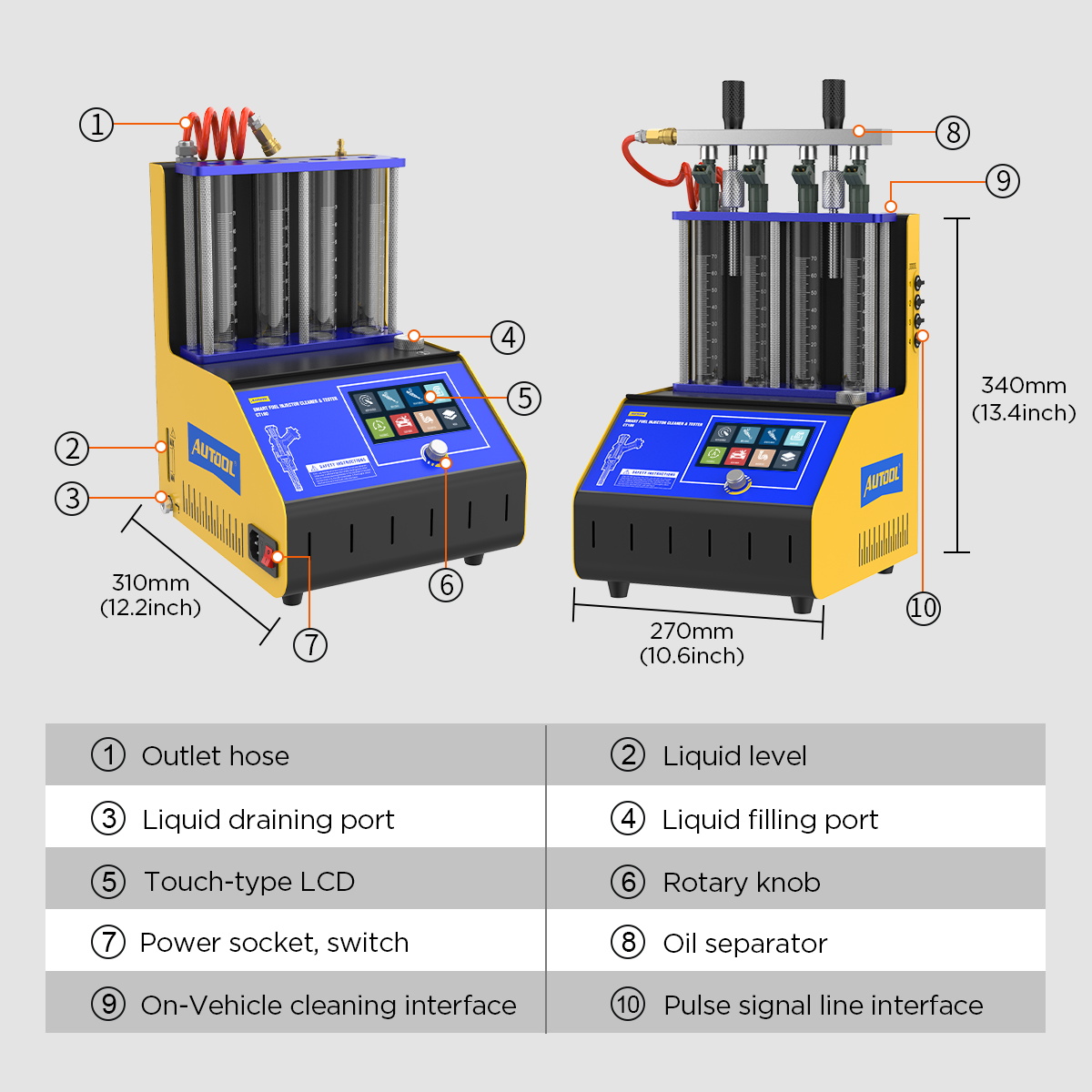

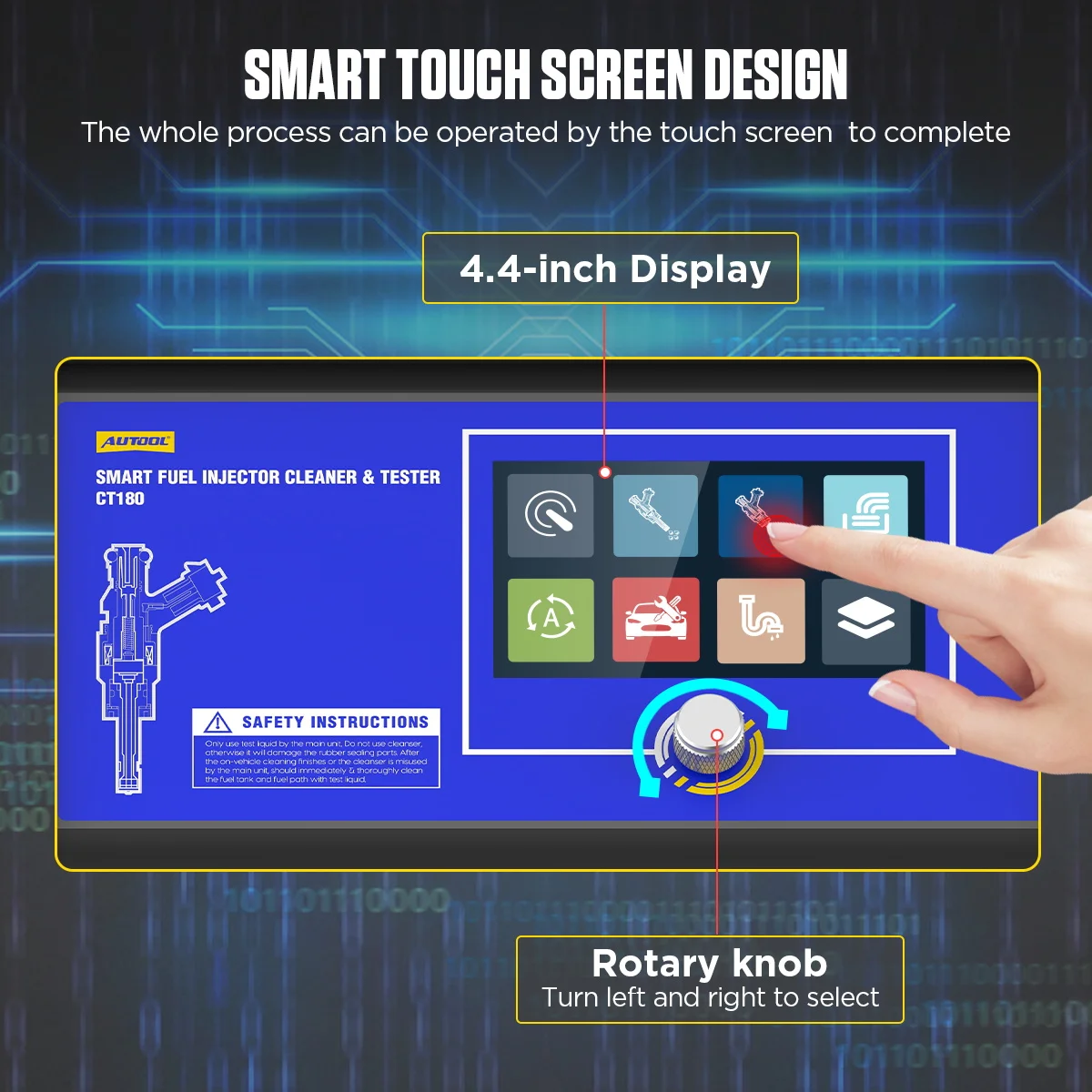

1.[Intelligent Control Panel Design]: To

deliver premium user experiences and make it more efficient to use, AUTOOL CT180

Fuel injector cleaner and Tester is designed with Touch Screen and Rotary Knob.

With large 4.4-inch screen display, it is easy to observe various working

parameters.

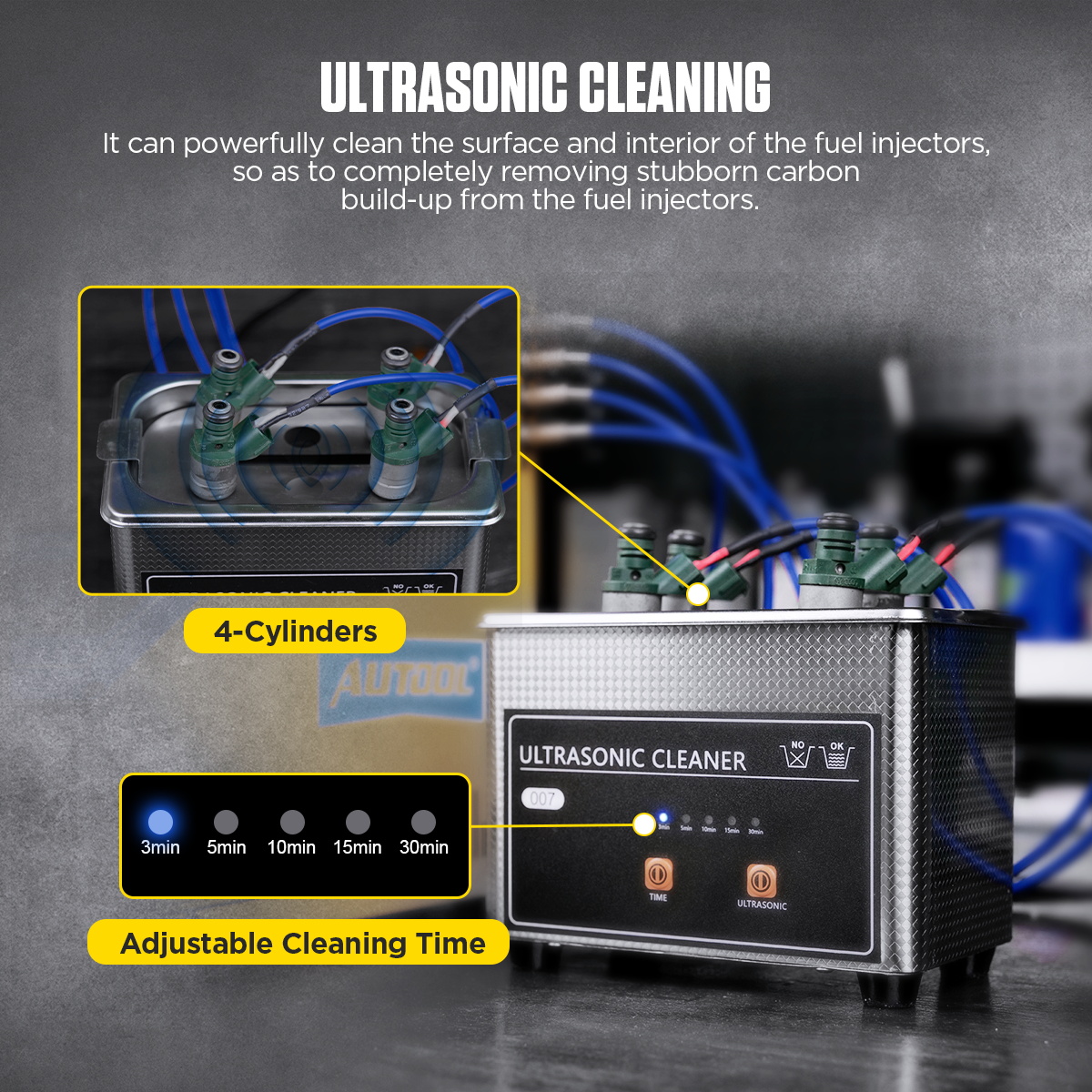

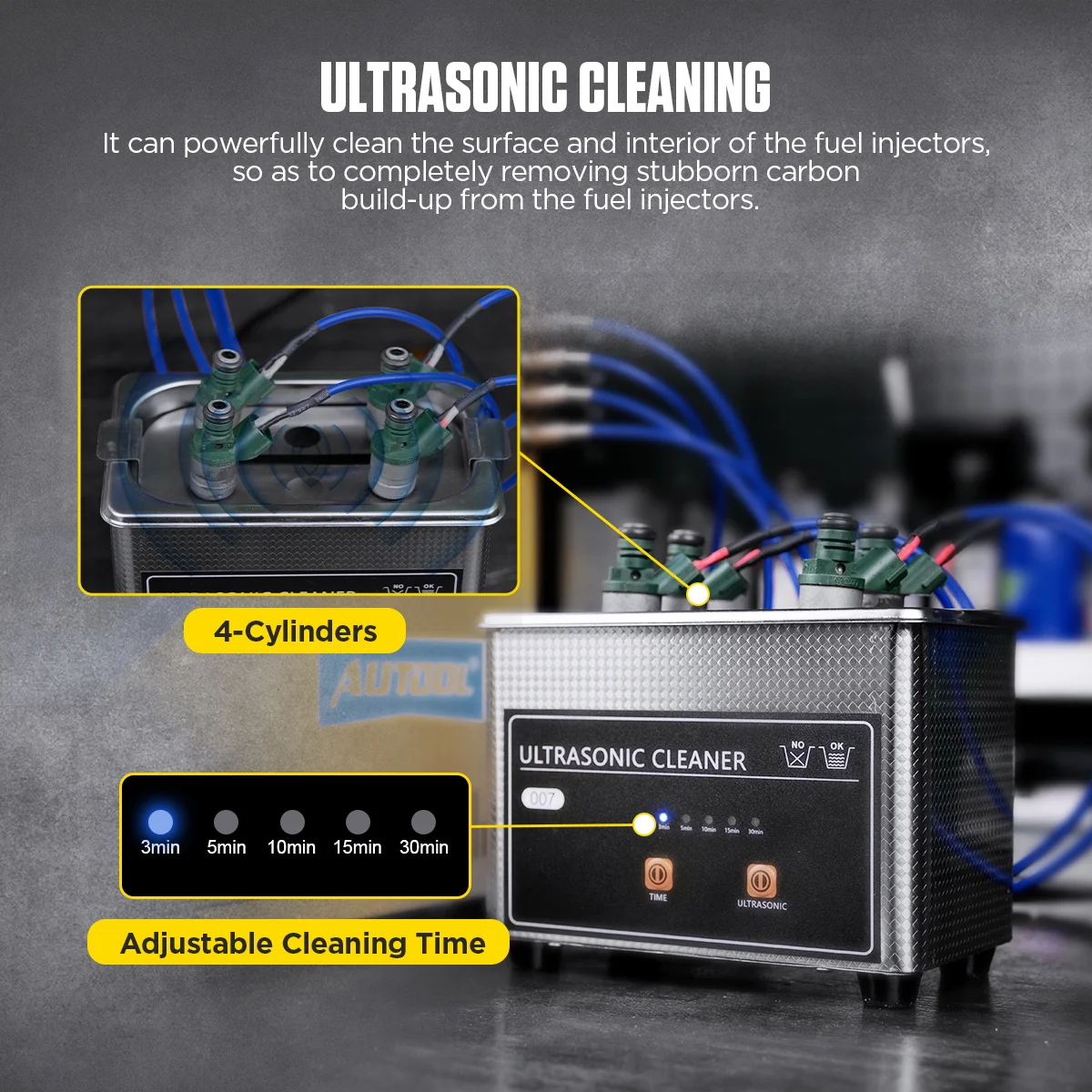

2.[Ultrasonic Cleaning Tech]: The AUTOOL CT180 intelligent

injector cleaner and tester is equipped with a separate ultrasonic cleaning

tank. The vibration signal generated by ultrasonic waves is applied to

powerfully clean the surface and interior of the fuel injectors, so as to

completely removing stubborn carbon buildup from the fuel

injectors.

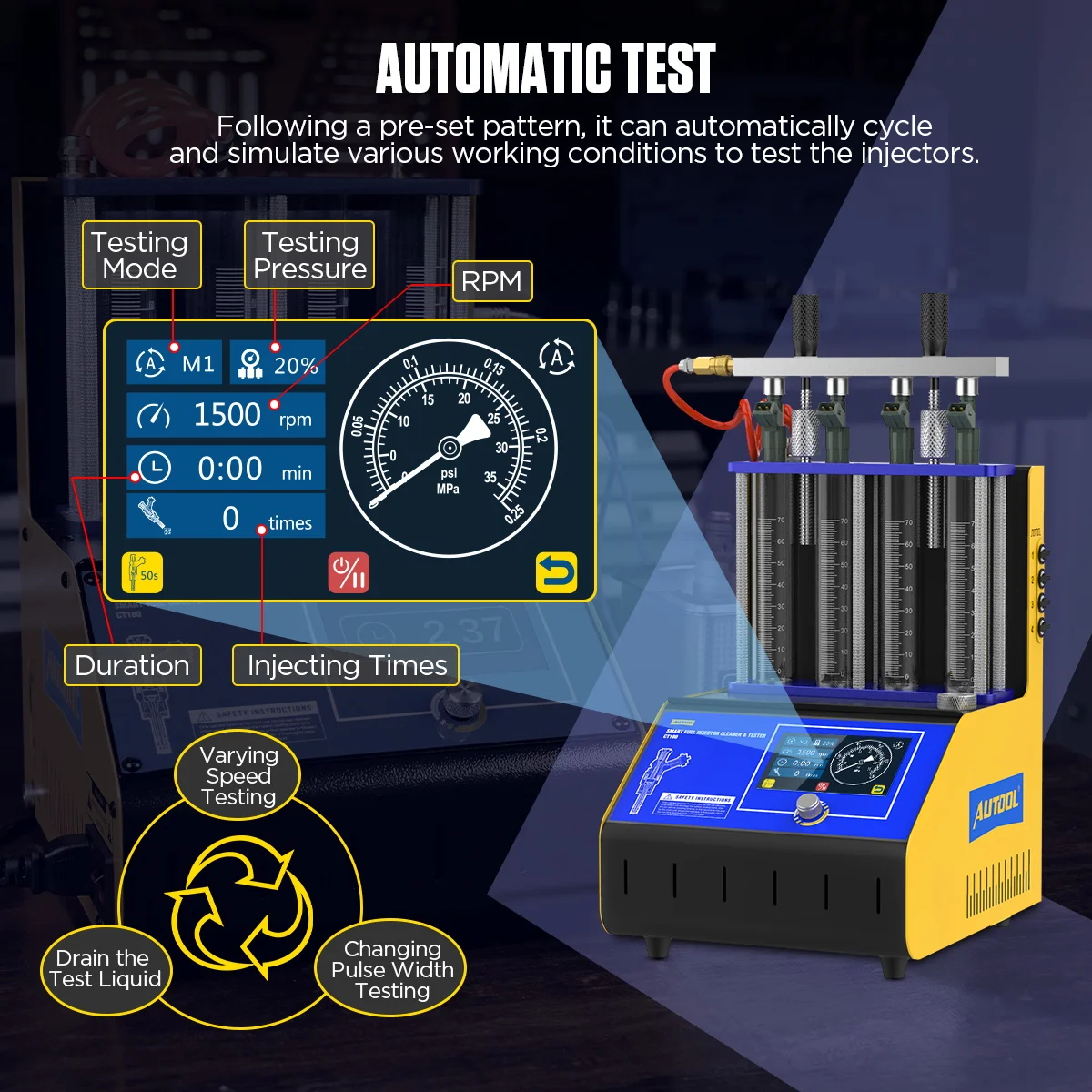

3.[Multiple Test Functions]: It can carry out Sprayability

test, Leakage test, Injecting Flow test, Automatic test and many other testing

functions. A variety of test parameters can be set to simulate injector testing

under various operating conditions.

4.[Backlight Design & Level

Gauge]:The glass tube can be observed through the level gauge during the test,

so that the injector flow can be determined whether the flow is normal. At the

same time, the backlight can assist in making the observation more

carefully.

5.[Three Years Warranty, Lifetime Maintenance]: For damage

caused by non-human factors, AUTOOL promises to resend parts for free within 3

years. For any needs, you are warmly welcomed to contact us and we will get back

to you ASAP within 24 hours.

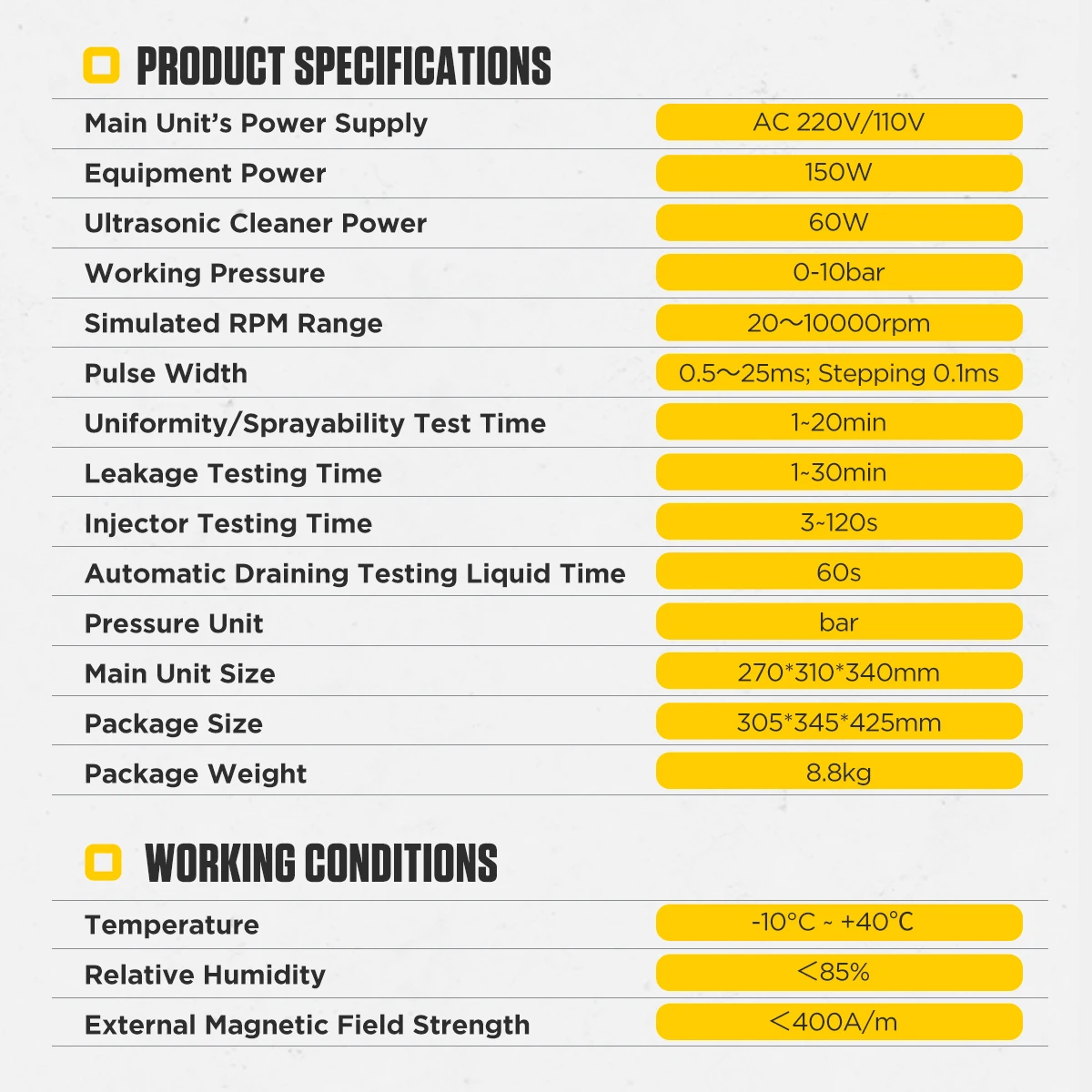

CT180 Car Fuel Injector Tester

Cleaner Specifications :

Working conditions:

Temperature:

-10~+40ºC;

Relative humidity: <85%;

Intensity of outer magnetic field:

<400A/m;

No flame within 2 meters.

Specifications:

Main

unit power supply: AC220V±10%, 50/60Hz; or AC110V±10%, 50/60Hz.

Main unit

power: 150W

Dimension of main unit: 27cm x 31 cm x 34cm

Ultrasonic cleaner

power: 60W;

Fuel pressure:0-10bar

Simulated RPM range:

20~10000rpm;

Pulse width: 0.5~25ms; step 0.1 ms;

Uniformity/Sprayability

test duration: 1~20min

Leakage test duration: 1~30min

Injecting flow test

duration: 3~120s

Automatic drain: 60s

Pressure unit: Bar, Psi, Kpa, mmHg,

Kg/cm2

Dimension: 305x310x340mm

Weight: 8.8kg (Varies according to

configuration)

Main Function:

1.Ultrasonic

cleaning;

2.Uniformity/Spray-ability test;

3. Leakage test;

4.Injecting

flow test;

5.Automatic test;

6.On-vehicle cleaning;

7.Reverse

flush.

Packing list:

1pc* AUTOOL CT180 Intelligent Fuel injector

cleaner and Tester Main unit

1pc* Ultrasonic cleaning tank

1pc* Testing

pad

1pc* Ultrasonic leaning stand

4pcs* Connector 1 (H19*25*10.5)

4pcs*

Connector 2 (H19*25*13.5)

4pcs*Fine-tooth joint(H19*25*M12)

4pcs*Coarse

joint(H19*25*G1/4-19)

3pcs*Plug (25*40*16.2)

4pcs*Reverse

joint(25*40*16.2)

2pcs*Adjusting stud (M10*78)

2pcs*Compression

screw(18*100*M10)

2pcs*Knurled nut(18*30*M10)

1pc* 4-oil

separator(28*16*213)

1pc*Funnel (58*50*8.0)

1pc* Wrench for Oil

draining(24*56*5)

20pcs* Sealing ring 7*2.65

4pcs*Seal ring

15.6*2.65

2pcs* power cables (EU US standard)

2pcs* Pulse signal

lines

Q&A:

1. No response at boot

Check whether the

fuse on the bottom of the right side of the machine is damaged. If it is

damaged, please replace the fuse (AC 250V/5A).

2. Oil leakage at the oil

separator assembly

Oil leakage at the oil separator, please check whether the

installed "O" ring is matched, and check whether it is deformed or damaged. If

it is not matched or damaged, please replace it;The two black adjusting screws

should not be too tight, too tight will also cause oil leakage of the oil

separator.

3. The oil pressure drops slowly

The oil pressure cannot

drop to zero within 1 to 2 minutes, and you can use the hex wrench to adjust the

relief valve counterclockwise.

4. The buzzer sounds long without oil

pressure

The machine has a lack of oil alarm function. When the liquid level

in the oil tank is insufficient, a sound will be emitted, and the oil pump and

fuel injection nozzle will be automatically turned off and returned to stop

later.In the state, the prompt sound will be closed automatically after adding

enough cleaning fluid. At this time, you must press the [Run] key to restart the

oil pump.

5. Must be pressed 'Drain key' twice to drain test solution

completely

The solenoid valve of the machine has an automatic shut-off

function within 15 seconds; more liquid in the glass tube may require multiple

drains.

6. The amount of cleaning and test solution added

When adding

cleaning fluid, the cleaning fluid in the ultrasonic box should not exceed the

connection port of the fuel injection nozzle; when adding test fluid, the

testing fluid should not exceed two-thirds of the glass tube level

display.

7.Problems with cleaning and testing 4 injectors

there is a

short circuit of the machine, which causes the protection of the machine to

restart.It may be that the resistance value of the fuel injector is too low or

there is a problem with the fuel injector. You need to find the problematic

nozzle and replace it with another normal nozzle for cleaning. If there is no

problem with the fuel injector, one of the pulse lines is damaged. There are

6pcs impulse lines, and each impulse line needs to be tested separately. If all

6pcs pulse lines can be used normally, this is the problem of the fuel

nozzle.

0 Stars of 5,0 Reviews.

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

Share your thoughts with other customers.

Write a reviewYou may also like

-

AUTOOL OBD2 Automotive Diagnostic Protocol Detector Break Out Box Tester OBDII Diagnostic Scan Tool Assistant CAN Test Box Fault

$35.0010% off

-

AUTOOL CS603 Automotive OBD2 Scanner Diagnostic Scanner Four-System Diagnostic Scanner Diagnostics Engine Transmission ABS SRS

$199.005% off

-

Hot sale Newly AUTOOL Obd2 16 Pin Extension Universal Extension Connector For ELM327/AL519/Easydiag Launch Obd Scanner Adapter

$9.0010% off

-

AUTOOL 8L Pneumatic Refueling Automatic Transmission Oil Machine Replacement Tool Car Gearbox Grease Injector Oil Tanker Tools

$49.0017% off

-

AUTOOL BT250 Circuit Tester Powerscan 6-30V Automative Power Probe Kit LED Display Voltage Polarity Locator Diagnostic Tool

$45.008% off

-

AUTOOL BT-50 For 12V DC Power Source Supply Cable Memory Saver ECU Power Interface/Connector OBD2 Vehicle ECU Emergency Power

$15.0021% off

-

Tel

+86-19892834301 -

WhatsApp