- WhatsApp:+86-19892834301

- Email: automantool@hotmail.com

- Skype:autoobdtop

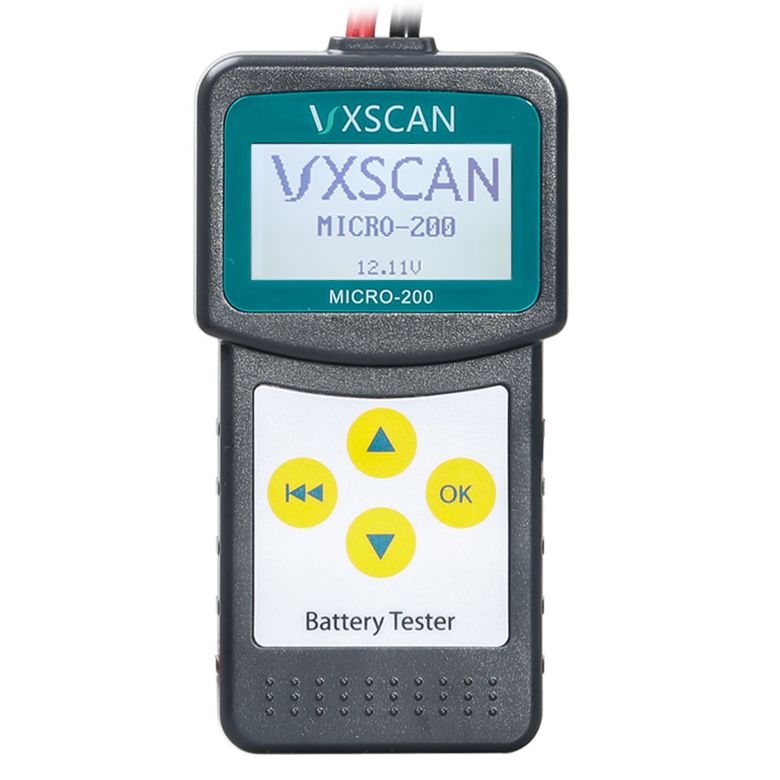

Car Battery Tester/Analyzer MICRO-200 for 12 Volt Vehicles

0 out of 50 global ratings

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

ratings| answered questions

0 global ratings

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

Fast Shipping & No Tax

US Check: Ship from US

UK Check: Ship from UK

EU Check: Ship from Czech

Looking for help? Please contact Whatsapp: +86-19892834301

- Shipping:

-

Free Shipping

Express Shipping ServiceEstimated delivery time: 3-5 Working Days

- Quantity:

- Stock:20

- Weight:

- 0.3 KG

- Package:

Related Download Files

MICRO-200 Car Battery Conductance

Tester

There are three language

versions:

AD112: Mainland

Version Japanese,

Korean, Russian, English

AD112-B: Nordic Language

version: English,

Dutch, Swiss, Finnish, Norwegian, Danish

AD112-C: Western European language

version: English,

French, German, Spanish, Italian, Polish

Product

specification:

1,One

year warranty and lifetime maintenance

2,Application:

12V automotive cranking lead acid battery and 12v car system

test

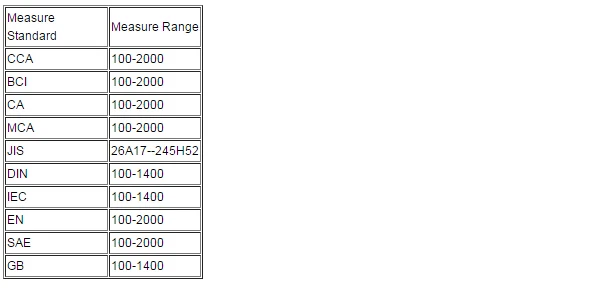

3,Measure Range:

4,Working

Environment Temp: -20℃-50℃

5,Special

test clip: Double conductor Kelvin clamp

6,Housing

Material: Acid-resistant ABS plastic

7,Measure

Range: 30AH-200AH

8,Voltage

Measure Range: 7-30VDC

How to

use:

1.Connect

the red test clamp with battery anode and the black one with cathode, the tester

will power on automatically.

Voltage battery below 7.0VDC can’t be tested properly, then press OK key to

continue.

2.According

to the tester, you can press UP/DOWN key to choose:

battery test

starting system test

charging system test

battery test result

print test result

elect language

Perform Battery

Test:

Select

the battery test and press OK key to continue:

Input

testing standard: the standard which you can see the front of the battery, such

as CCA, BCI, DIN. If you can’t find any info about the standard,

you

can choose GB standard. Choose GB standards would lead little

tolerance.

Input

rated capacity: you can see the starting current standards in front of the

battery .Such as BCI/300A.

Then

press OK key to start testing.

Note:

For

power loss battery (such as a vehicle for a long time on hold, the battery is

not charged in time; forget to close the lights, the doors resulting in serious

loss of battery electric vehicle and can not be started, etc.), in the actual

testing process may also be prompted to "Please replace the

battery."

for

such batteries, please consult the battery manufacturers, and then

tested.

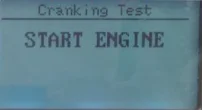

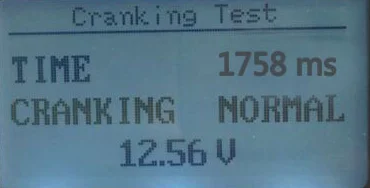

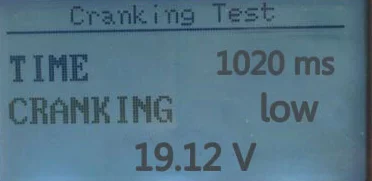

Starting system

test:

After

entering the second start system test functionthe press OK key as

follows:

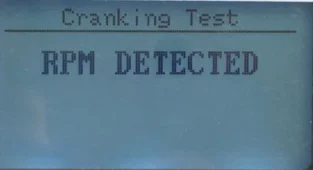

Starting

the engine as prompted, the tester will automatically complete the cranking test

and display the result.

Normally,

cranking voltage value lower than 9.6V is regarded as abnormal and it is OK if

it is higher than 9.6V.

Test

result of the tester includes actual cranking voltage and actual cranking

time.

When

the cranking test is abnormal, battery test result will also be displayed at the

same time.

This

is for the convenience of the maintenance personnel to quickly know the whole

state of the starting system according to the data.

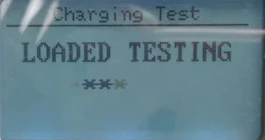

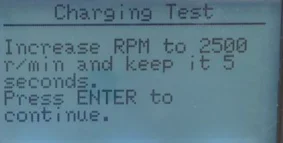

Charge system

test:

When

enter the charging test, the tester will prompt "Loaded

testing"

Note: Do not shut down the engine during

the test. All electrical appliance and device are in OFF state. Turn on/off any

electrical

appliance

in the vehicle during the test will affect the accuracy of the test

result.

Operate

accordingly to increase the engine rotating speed to 2500turns, and keep for 5

seconds.

Tester

starts the charging volt test after increase rev detected.

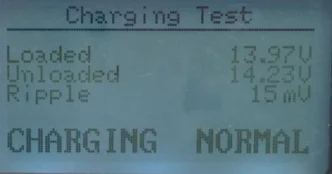

After

the test finished, tester displays the effective charging volts, ripple test

result and charging test result.

NOTE: If

no increase rev detected, it shall be the fault of generator regulator or

connection with battery failed. Tester will try 3 times to further detect, if

still failed, it will skip the increase rev detect and the test result displays

"No Volt Output".

Check

the connection between generator and battery, then retest.

Charge Test

Result:

1.

Charging Volt: Normal. The generator output normal, no problem

detected.

2.

Charging Volt: Low. Check drive belt of the generator whether slip or running

off. Check the connection between generator and battery is

normal or not. If both of the drive belt and the connection are in good

condition, follow the manufacturer's suggestion to eliminate generator

fault.

3.

Charging Volt: High. Since most of the vehicle generators are using internal

regulator, the generator assembly has to be replaced.(Some old

style

cars are using external regulator, then directly replace the regulator.) The

normal high volt of the voltage regulator is maximum 14.7±0.5V.

If charging volt is too high, it will overcharge the battery. Therefore, the

battery life will be shortened and troubles will be caused.

4.

No Volt Output. No generator volt output is detected. Check the generator

connection cable, the drive belt of generator and engine whether

normal or not.

5.

Diode Test: Through the test of charging current ripple, tester will find out

whether the diode is normal or not. When ripple volt is too

high,

it proves at least one diode is damaged. Check and replace the

diode.

View test

result:

After

entering the forth function, then press OK key you can view the final test

result.

Print test

result:

About

Printing function, please contact with customer service to get the download

link.

Select a

language:

After

entering the language function, can press up/down key to choose

it.

Package

List:

1pc

x MICRO-200

0 Stars of 5,0 Reviews.

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

Share your thoughts with other customers.

Write a reviewYou may also like

-

OEM FK729D370AA FK729D370AC FK729D370AE FK729D370AF Fuel Pump Module for 2015 to 2019 Years Land Rover

$65.0013% off

-

All-Sun Professional EM276 Injector Tester 4 Pluse Modes Powerful Fuel System Scan Tool

$27.007% off

-

OEM Jaguar Land Rover Blank RFA Module J9C3 with Comfort Access contains SPC560B Chip and Data

$309.0011% off

-

OEM A212 9003 508 A2129003508 Fuel Pump Control Module for A207/403/404 Mercedes-Benz GLK350 2010-2012

$55.0015% off

-

Hantek 1008B 8 Channel PC Oscilloscope/DAQ/8CH Generator

$109.008% off

-

Handy Smart YANTEK YD308 Diagnostic Tool auto Circuit Tester Covers All The Function of YD208

$169.006% off

-

TYPE-BMW2-433 Universal Programmable TPMS Sensor

$23.008% off

-

Tel

+86-19892834301 -

WhatsApp