- WhatsApp:+86-19892834301

- Email: automantool@hotmail.com

- Skype:autoobdtop

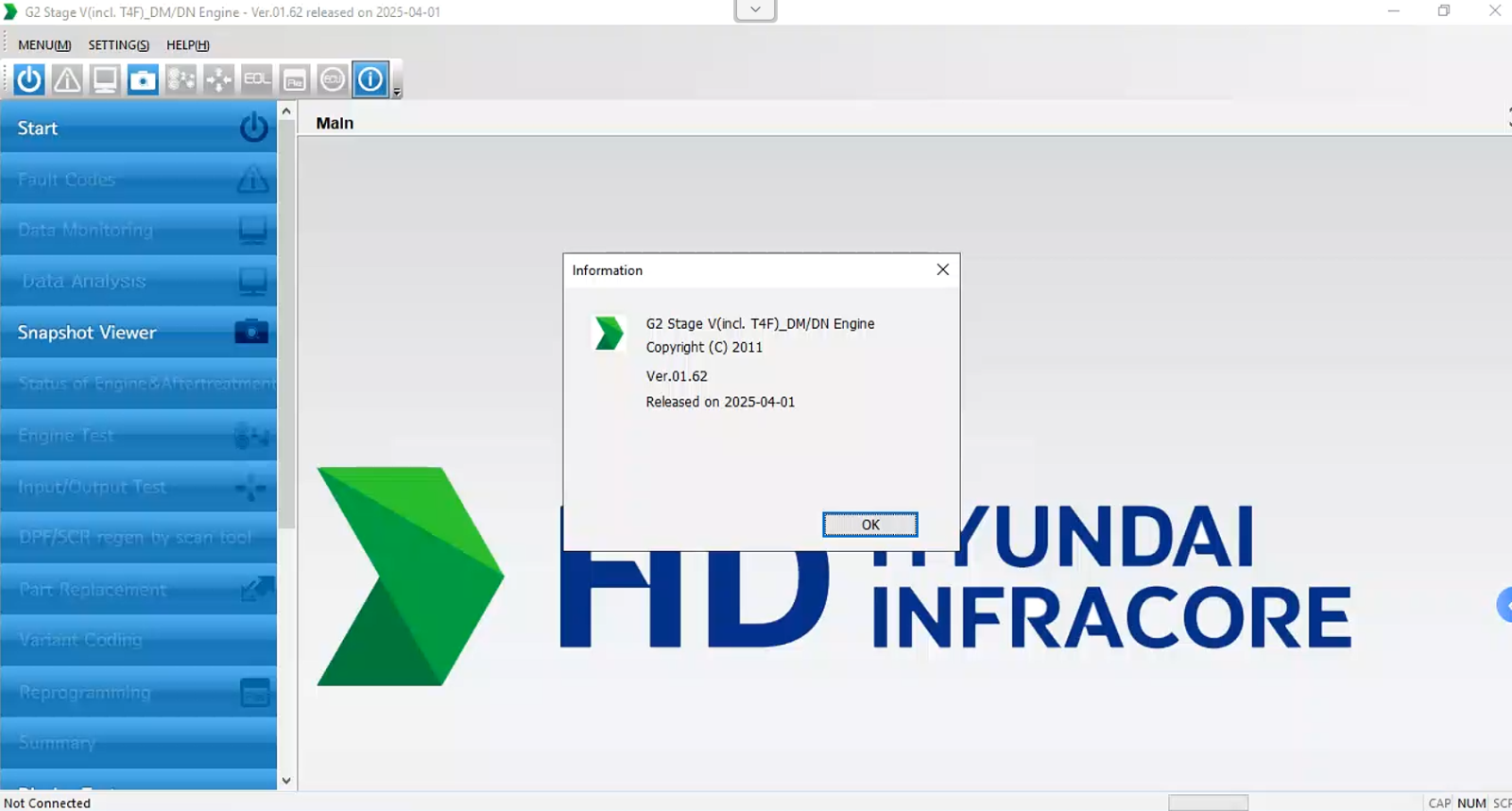

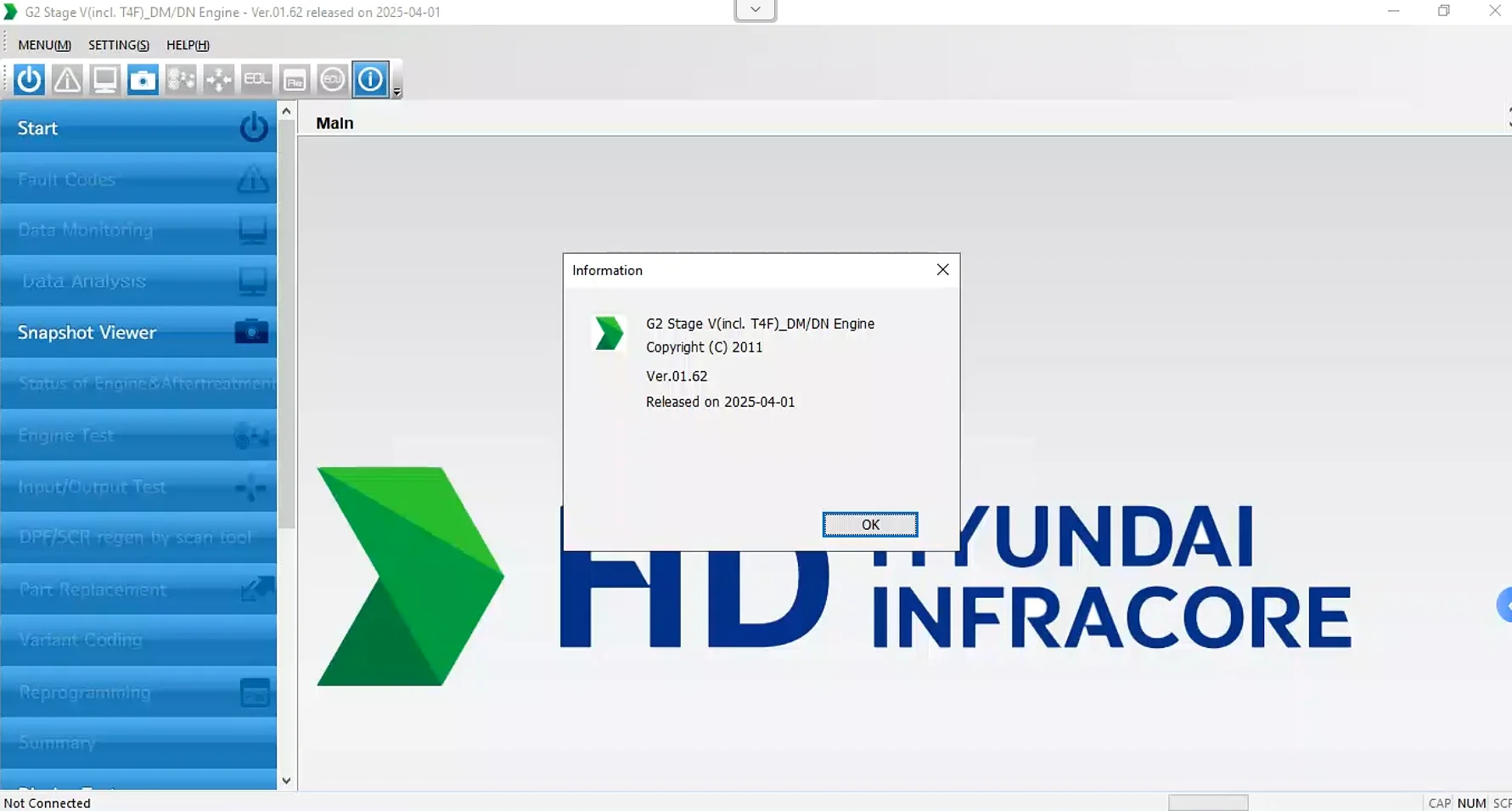

DOOSAN G2 STAGE V HYUNDAI INFRACORE G2 STAGE V (INCL. T4F) DM-DN ENGINE 01.62 [2025.04]

0 out of 50 global ratings

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

ratings| answered questions

0 global ratings

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

Fast Shipping & No Tax

US Check: Ship from US

UK Check: Ship from UK

EU Check: Ship from Czech

Looking for help? Please contact Whatsapp: +86-19892834301

- Shipping:

-

Free Shipping

Express Shipping ServiceEstimated delivery time: 3-5 Working Days

- Quantity:

- Stock:32

- Weight:

- 0.1 KG

- Package:

Related Download Files

DOOSAN G2 STAGE V HYUNDAI INFRACORE G2 STAGE V (INCL. T4F) DM-DN ENGINE 01.62 [2025.04]

Doosan G2 Stage V(incl. T4F)_DM_DN Engine Features:

Size:200MB

Date:2025.04

Version:01.62

OS requires:Win7,Win8,Win10 and Win11

Compatible Interface:Doosan Diagnostic Tool

Price only for one PC installation and activation

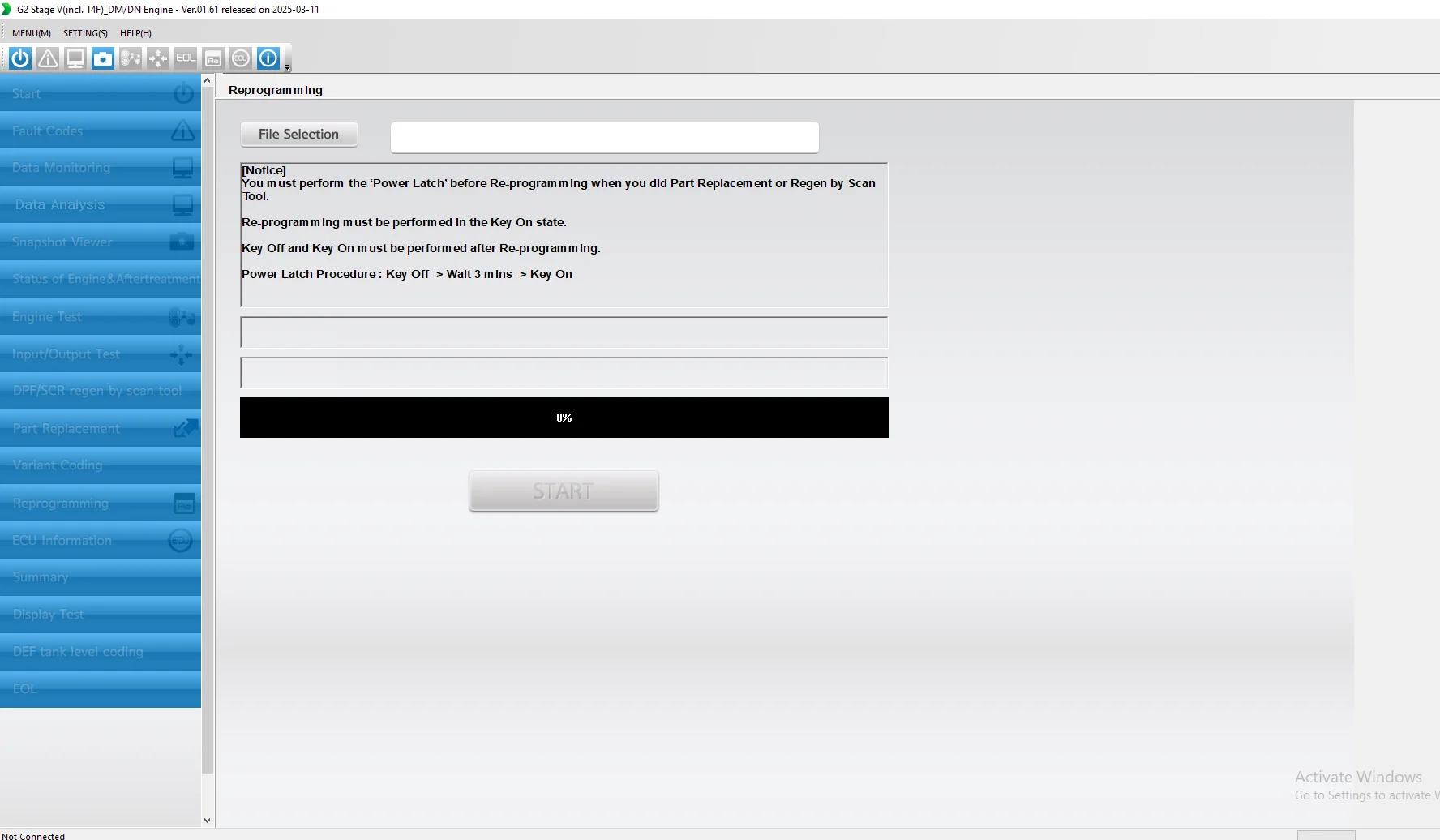

Doosan G2 Stage V(incl. T4F)_DM_DN Engine Functions:

Fault Codes

Data Monitoring

Data Analysis

Snapshot Viewer

Status of Engine & Aftertreatment

Engine Test

Input/Output test

DPF/SCR regen by scan tool

Part Replacement

Variant Coding

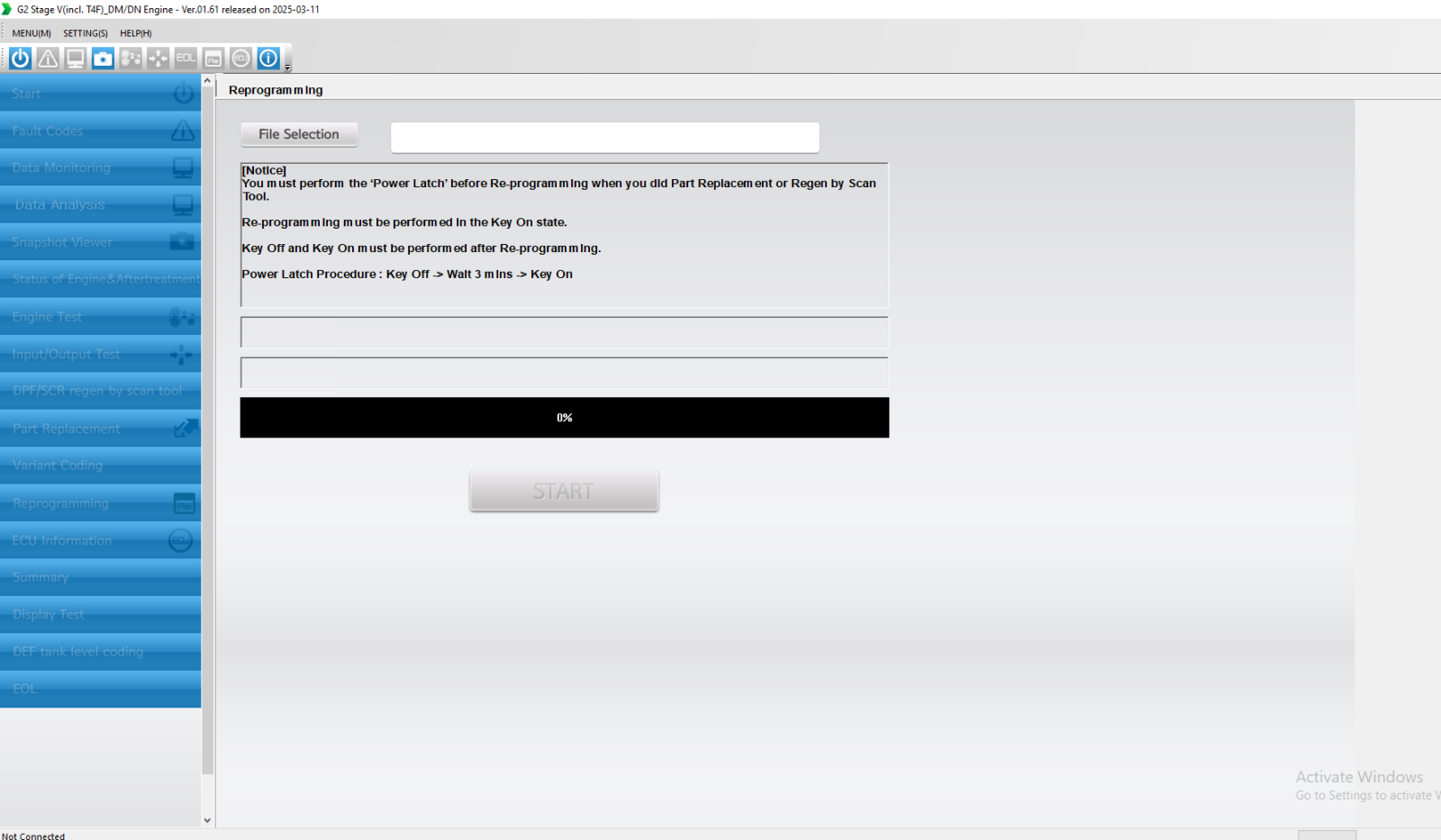

Reprogramming

ECU information

Summary

Display Test

DEF tank level coding

The Doosan Diaanosic Tool G2 Stage V (including T4F) is an essential sofware solution for diagnosing and maintaining heavy equipment tis designed tosupport compliance with stingent emissions regulations while optimizing engine performance. This tool ofers a range of features, including compatibility with Windows 11 and support for multiple languages. lts robust diagnosic capabilies make it a valuable resource for technicians and mechanics across various industries

Features of Doosan Diagnostic Tool G2 Stage V

The Doosan Diagnostic Tool G2 Stage V offers a vanety of features designed to enhance the diagnostic and malntenance processes for heavy machinery.

Its advanced capabilities ensure optimal performance and compliance with stringent emission standards.

System Compatibility

Operating System: Windows 11 (64-bit)

The sofware is specicaly developed to operate seamlessly on Windows 14 (64-bit, This ensures that users can leverage the latest advancements inoperating system technology while working with diagnostic tools. The compatibility with Windows 1f provides an intuitive interface, enhanced securtyfeatures, and improved overal performance for the software. Technicians can rely on a stable environment that supports effcient diagnostics and repairs

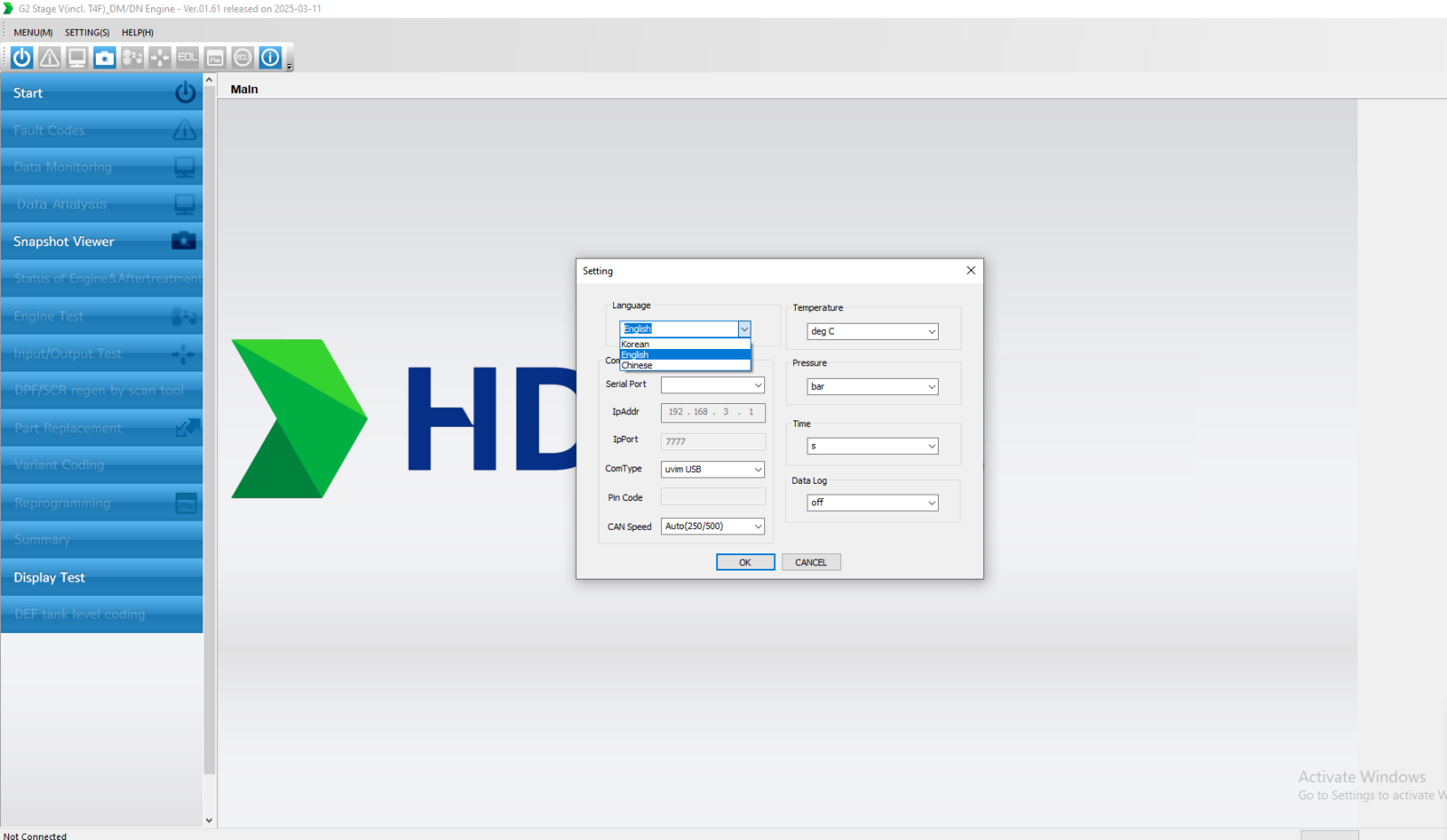

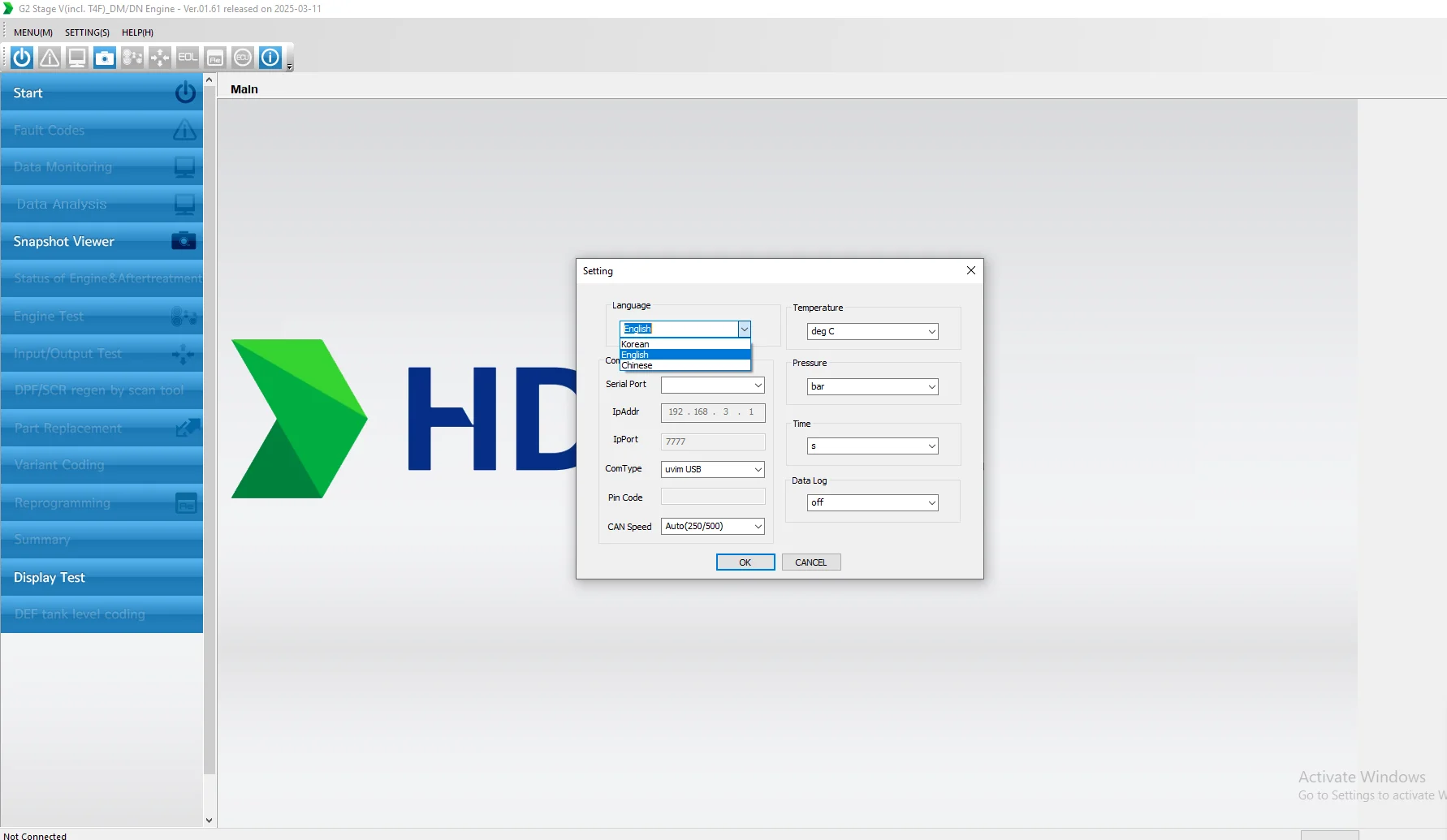

Database Languages: English and Korean

To cater to a global audience.the Doosan Diagnostic Tool G2 Stage V supports multiple languages, particularly English and Korean. This multilingualsupport enhances accessiblty for technicians and users from diverse regions, streamlining communication and reducing bariers during the diagnosiprocess. The ability to switch languages is beneficial in multlingual workplaces or when collaborating with international teams.

Functionality

Diagnostic Capabilities

This tol boasts comprehensive diagnostic capabiliies talored for a wide range of Doosan equipment. t facilitates rea-time diagnostics, allowing techniciansto quicky identfly issues within engines and machineny. With advanced algorithms, the software analyzes data from various engine sensors, enhancingprecision in troubleshooting. An effective diagnostic tool saves time and reduces downtime in operations.

Calibration Options

The Doosan Dianosic Tool G2 Stage V includes robust calibration options that ensure engines are performing optimally. The callbration processes adiustthe parameters of the engine based on the specifc needs ofthe machinery to meet performance and eficiency standards. This functionality plays a crucialrole in maintaining compliance with environmental regulations and improving fuel efficiency.

Maintenance Support

This software provides essential maintenance support, equiping users with the necessary tools and information for regular upkeep. Rouine maintenance iscrical for prolonging the lifespan of heayy machineny and avoiding costly repairs The tool assisis in scheduing maintenance fasks and provides remindersensuring that machinery remains in peak operating condition.

Testing and Repairs

In addition to diagnostics,the Doosan Diagnostic Tool G2 Stage V ofers features for testing and repair processes. Technicians can perform varous tests toevaluate the funcfionally of dierent components within the machinery. This indudes tesing electical svstems, hvdrauic functionalties,. and tansmissionoperations. The ability to execute repairs directly within the software simplifies workflows and streamlines the repair process.

Compatible Engines and Equipment

Understanding the compatibility of the Doosan Diagnostic Tool G2 Stage V with various engines and equipment is crucial for efective operations acrossmultiple sectors, This section outlines the diferent tvpes of machinery that can benefit from this diaanostic tool

Heavy Equipment Doosan

The Doosan Diagnostic Tool G2 Stage V is specificaly designed to work seamlessly with a range of heavy equipment produced by Doosan. Thiscompatibility ensures that heavy machinery can be diagnosed efficiently, optimizing performance and minimizing downtime

Construction Machinery

In the construction sector, the tool has proven indispensable. lt is tailored to diagnose and maintain the folowing machinery.

*Case Construction

Case construction equipment is widely utlized in various projects, and the diagnostic tool supports its engines for effective maintenance

*Holland Construction

This eauipment often operates under challenging conditions, making precise diagnostics essential for reliable operation and longevitly

*JCB ServiceMaster

Naval and construction machinery from JCB can benefit from enhanced diagnostic capablities using the Doosan tool, ensuring optimalfuncionality.

*New Holland

The integration of this tool with New Holand equipment offers users the ability to maintain their machinery eficiently and efectively, even in demandingenyronments

Agricultural Machinery

Aaricultural applications are another significant area where this diagnostic tool excels, encompassing a varety of machinery

*Tractors

The diagnostic capabilities for tractors help ensure they run smoothly, which is vital during peak farming seasons

*Harvesters

For harvesters, timely diagnostics can prevent potential issues that could delay or disrupt the harvest process

Industrial Uses

This diaanostic tool is not imited to only construction and aaricutural machinery. it extends its applicability to vanous industial machines as wel.

*Marine Engines

The functionality of the diagnosic tool ensures that marine engines peform optimally, complying with environmental standards and operationalrequirements

*Automotive Engines

In the automotive sector, accurate dianostics enhance the longevity and peromance of engines, minimizing the chances ofserous mechanical fallures

Diagnostic Kits

For comprehensive diagnostics, several kits are compatible with the Doosan tool, enhancing its functionality.

UVIM Diagnostic Kit

This kit allows for detailed inspections and adiustments, ensuring a deep understanding of enaine performance metrics.

Interfaces UVlM Diagnostic

Diferent interfaces within the UVlM range support extensive diagnostics, making the work of technicians more straightforward and elficient

Nexiq USB Link

The Nexig USB Link enhances connectivity and data transfer capabilties between the diagnosic tol and vanious machinery models, further streamlining the diagnostic process.

Doosan G2 Stage V(incl. T4F)_DM_DN Engine Update Log

Applying Security Access Logic

Updated uVIM/ Diagnostic Scan Tool User Manual

Update uVIM/Diagnostic Scan Tool User Manual v1.40

– [User Manual] uVIM_Diagnostic Scan Tool_ENG_v1.40.pdf

7.3 Deleted ECU Information Menu

The contents of Summary contain ECU information. So, ECU information menu is replaced to Summary menu.

Added SUFFIX Description on Summary Menu

Available for DM01/02/03, DN02/03

It is configured so that the product description is not displayed on the diagnostic scan tool if it is not defined.

– SOS_G2_STAGE V_T4F_DM01_02_03_DN02_03_20241015.xlsx

Changed the status of an unused variable – Engine Oil Temperature

. Engine oil temperature is not used by G2 STAGEV/T4F application. So, value of variable,Oil_tSwmp, is displayed and saved like “Not Supported” to prevent confusion of users in the field.

Updated Visual C++ 2008 Package and Visual C++ 2022 Package

. Visual C++ 2008 and 2022 package is applied to solve the issue of forced termination of the diagnostic scan tool when recording data during service regeneration.

. if the program is already installed on the user’s PC, it is configured to automatically bypass the installation on the diagnostic scan tool without prompting the user.

Modified Input/Output Test Condition – Signal Test of Coolant Valve

. When testing the I/O test-Signal Test of Coolant Valve, set the value to ON and press START to continuously send ON request messages until the STOP is pressed. Modifying the logic so that the valve can be controlled.

Added CE Lamp Description

. DFES_stErrLamp: DFES error lamp demands

================ history ==================================

sw ver: 01.32

date : Sep 04, 2023

– The variable “Com_tiEPAYrDft_C/Com_tiEPAMthDft_C/Com_tiEPADayDft_C” is added

sw ver : 01.31

date : Jun 27.2023

– Improved the scan tool to automatically recognize CAN speed

sw ver : 01.30

date : May 11, 2023

– Updated Trouble shooting guide(Revision 1.76)

– Tampering inducement group is updated.

(P05ED, P1044, P1045, P214F, P215E, P215F, P21DD, P221C, P221D, P221E, P221F are added.)

– DPF regeneration enable/inhibit SCB fault diagnosis time is updated.

(P25BB, P25BC)

– Overfilling is added to the reason of P250F

(Engine oil level is too low (Low step3)).

sw ver : 01.29

date : APR 7, 2023

– Modified the fault number of “DFES_numDFC”(No 263 -> No 260)

– Changed to HD Hyundai infracore Templete

sw ver : 01.28

date : Mar 29, 2023

– Added CAN speed 500 kbps

– Company Logo Changed (Inc. icon)

sw ver : 01.27

date : Feb 28, 2023

Changed the address of 5 variables(V800)

sw ver : 01.26

date : Feb 02, 2023

– Changed the test conditions of “DPF/SCR regeneration by scan tool”

– Modified the purpose of “SCR complete test

– Changed the wording of the dosing quantity

sw ver : 01.25

date : Dec 22, 2022

– The variable “SIGNALS_Exh_tOxiCatUs_s” in the Freeze frame is modified as follows:

=> DOC inlet temperature (Model) → DOC inlet temperature (Sensor)

– Modify the value of a variable (AirCtl_rDesValOfs / ASMod_rEGR)

– Update Variant coding => Delete C,D parts of the air filter

sw ver : 01.24

date : Nov 04, 2022

– Add the status of the variable “PFlt_stSysFail”

– Modified the reprogramming item(See next page for more information)

sw ver : 01.23

date : Oct 12, 2022

– Update User Manual

Correct errors and change to hyundai template

sw ver : 01.22

date : 2022-09-23

– Corrected the failure to read the latest program date of the ECU

– Changed logic to allow fault codes to be deleted only when the engine is stopped

sw ver : 01.21

date : 2022-08-12

– Added an 8-digit IQA code

* Injector Quantity Adjustment

sw ver : 01.20

date : 2022-07-18

– P2463 fault reason is updated.

– The connector pin definition of PWM control type FAN is updated. (P028A, P028D, P028E, P0527, P0528, P0529)

– Starter relay fault(P0615/P0616/P0617) reason is updated. (“Poor battery” is added.)

– Typo of P0545 SPN-FMI fault code is updated. (E002789-03 → E002789-04)

– Change variable to recognize “DPF” specification

DFC_DisblMsk.DFC_TPFltUsSRCMax_C -> DFC_DisblMsk.DFC_PPFltDiffSRCMax_C

sw ver : 01.11

date : 2022-07-04

– modified option information.

sw ver : 01.10

date : 2022-06-07

– Added terminal diagram to check sensor value

– Modified array of variables in snapshot

– Uniform variable name for scan tool

– Add an English variable name to the top of a Chinese variable name

0 Stars of 5,0 Reviews.

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

Share your thoughts with other customers.

Write a reviewYou may also like

-

Caterpillar CAT Forklift MCFA + PUBLICATIONS PARTS catalouge +Service manual 2019 NEW

$149.0012% off

-

2025 GTS+ One Year Online Access for GTS+ Agent Lite Software for Toyota for Lexus Diagnostic Scantool Global TechStream+ Work with J2534

$1499.004% off

![Tadano Cranes Spare Parts Catalog [2020.05] Offline & Tadano Faun Full DVD Manual new update](/upload/202406/21/202406210213260063.jpg)

-

Tadano Cranes Spare Parts Catalog [2020.05] Offline & Tadano Faun Full DVD Manual new update

$479.004% off

-

Kobelco Crane Parts Manual 2024.09

$249.007% off

-

Tel

+86-19892834301 -

WhatsApp