- WhatsApp:+86-19892834301

- Email: automantool@hotmail.com

- Skype:autoobdtop

2020 Caterpillar SIS CAT SIS 2020 Service Information System

0 out of 50 global ratings

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

ratings| answered questions

0 global ratings

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

Fast Shipping & No Tax

US Check: Ship from US

UK Check: Ship from UK

EU Check: Ship from Czech

Looking for help? Please contact Whatsapp: +86-19892834301

- Shipping:

-

Free Shipping

Express Shipping ServiceEstimated delivery time: 3-5 Working Days

- Quantity:

- Stock:32

- Weight:

- 0.1 KG

- Package:

Related Download Files

2020 Caterpillar SIS CAT SIS 2020 Service Information System

Note:

After receiving the payment, we will get software well installed by teamviewer.

Brand: Caterpillar

File Size: 230 GB

Language: English, Spanish, Italian,

Chinese, Mexican, German, French

Compatible OS: Windows

7 32 bit, Windows 7 64 bit, Windows 8/8.1 32 bit, Windows 8/8.1 64 bit, Windows

10 32 bit, Windows 10 64 bit

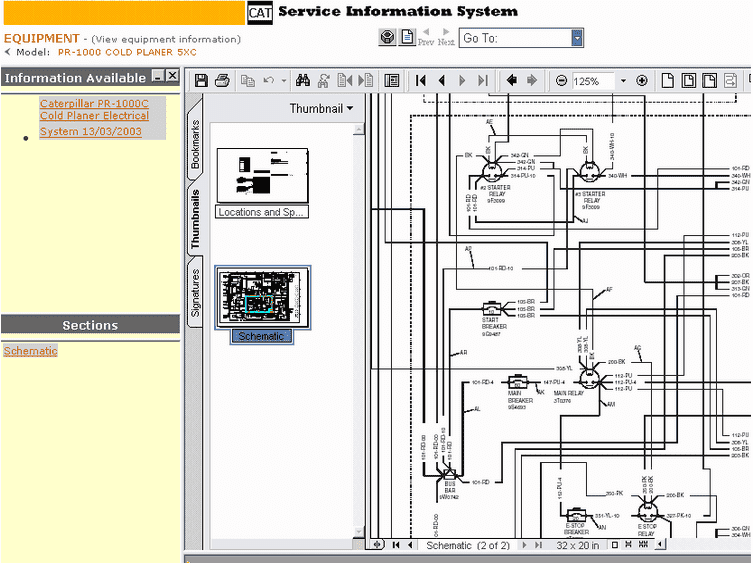

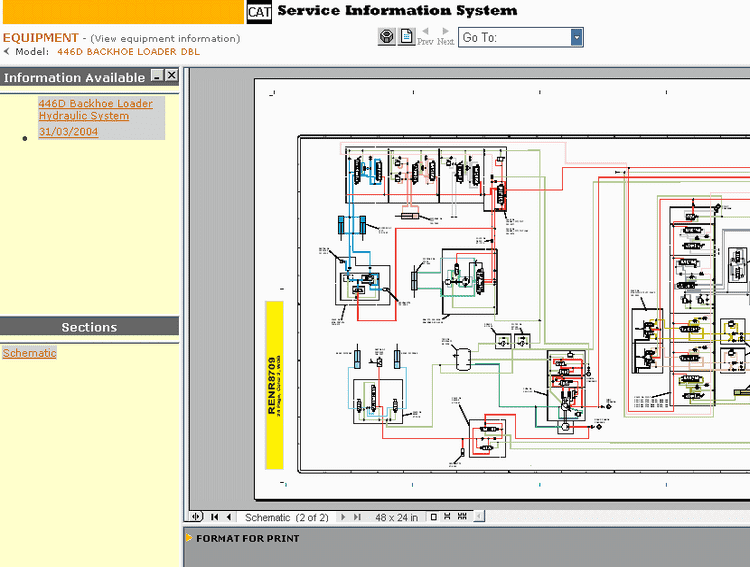

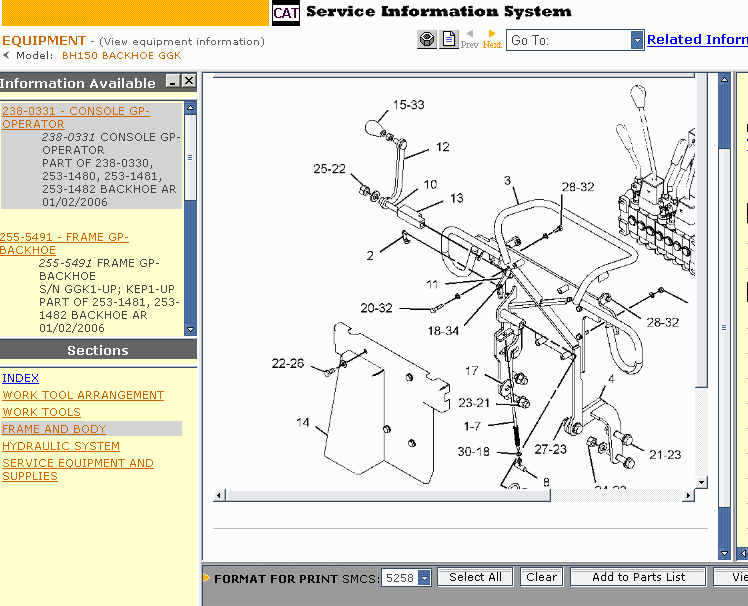

2020 Caterpillar

SIS Product

Description

Service

Information about the brand new release of the Caterpillar database - January

2020.

Caterpillar SIS (CAT SIS)

2020(replacing 2019/07 version) was developed for

maintenance and repair of the full range of cat vehicles, includes guidance on

repair equipment and machinery caterpillar, program help diagnose production

caterpillar, operating instructions spare parts and equipment caterpillar. All

pages in this online guide will enable you to quickly and easily find the

required information about the machine, also, helps specialists to calibrate

equipment caterpillar, diagnose it and troubleshoot equipment to solve any

problems. Electronic repair manual caterpillar SIS 2019 was written especially

for engineers and will be useful to all interested in the given

direction.

Publication

date: 2020

The Caterpillar SIS 2020 (3D

pictures) complete set contains the

full information on spare parts, repair, electric circuits and etc. SIS has been

tested using Microsoft Internet Explorer 5.5/6.0 on these platforms: Windows

2000 & Windows XP, VISTA and Windows 7.

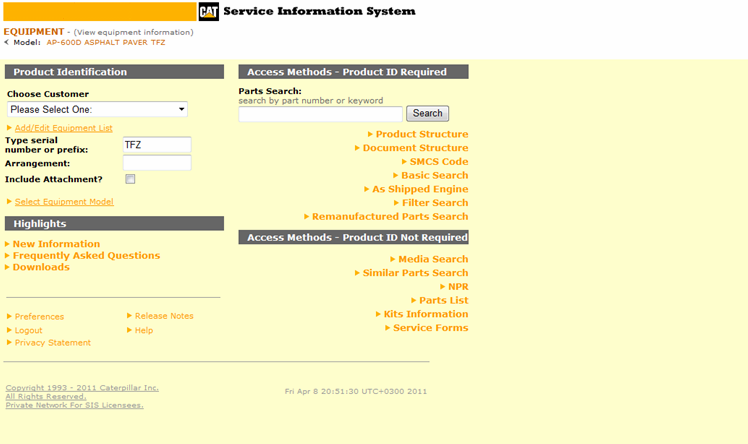

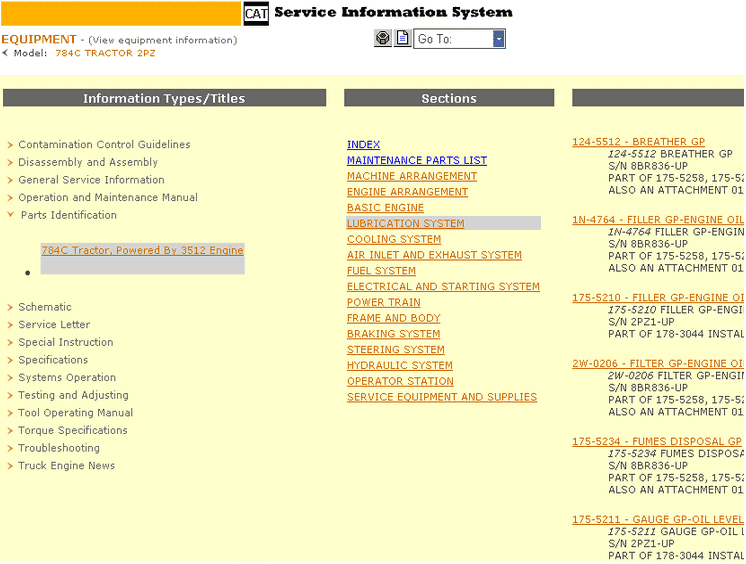

SIS

is the electronic service tool that Caterpillar dealers, customers and employees

rely on for their parts and service information needs. SIS provides information

for all Caterpillar machines and engines from 1977. SIS is available on the

Internet, DVDs and a network version based on the DVD standalone

application.

SIS

Web is updated continually and is the most complete and up to date version of

SIS. SIS DVD and Network SIS use the same information that is located on the

monthly data DVD'S. The time required to stage and ship the DVD'S to Dealer's

and Customer's accounts for the delay in information that may be available from

SIS DVD/Network.

SIS DVD is

the standalone version of SIS and is required when the Caterpillar Inc. server

for either SIS Web or the Dealer server for Network SIS is not available. Field

Mechanics may be the largest group that uses SIS DVD. All three versions of SIS

require an Internet Browser to display SIS information.

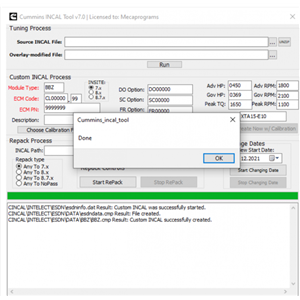

Caterpillar STW

The

Service Technician Workbench is an integrated package of software tools,

designed to assist the Caterpillar Service Technician during the machine repair

process.

STW

provides common installation of the following service software applications: STW

Toolbar (STW Lauchpad), Service Information System (SIS), Cat Electronic

Technician (Cat ET), CBT Component Based Troubleshooting (CBT), Technical

Analisis I (TA1) & Technical Analisis II (TA2), and Service

Report.

STW Features:

Allows

user to send data from SIS, TA and Cat ET to an Electronic Service Report. All

information about the repair is in one location.

Allows

user to attach Cat ET Warranty Reports to the STW service report.

Allows

user to attach digital photos to further document the repair.

A

single source of support ? DDS Support Center

Electronic

service reports are easier to archive than paper service reports.

Integration

between Component Based Troubleshooting (CBT), Service Information System (SIS),

Cat Electronic Technician (Cat ET), Flash File Search and Service

Report.

The

DBS Upload utility increases dealer efficiency by eliminating the need for the

technician to re-type data into the service report, already created in DBS. This

information is sent from DBS to STW to create a STW service report.

STW Lauchpad

The

STW Launchpad allows to you: Conveniently launch Service Software Applications,

Manage some common SIS/CBT preferences.

Families/Models/Prefixes

BROOM-ANGLE, SAHL BROOM, BCG

GENERATOR SET, 3516B, EDG

INDUSTRIAL ENGINE, C7.1, G9R

GENERATOR SET, C6.6, LC6

EXCAVATOR, 336F LH, LTP

MOTOR GRADER, 12M 3, N9F

MOTOR GRADER, 160M 3, N9L

ARTICULATED TRUCK, 725C, TFB

WHEEL TRACTOR-SCRAPER, 621K, WTL

ENGINE - MACHINE, C9.3, WYE

EXCAVATOR, M315D 2, CH3

GENERATOR SET, 3516B, JCY

HAMMER, B30, MAY

MOTOR GRADER, 140M 3, N9M

MOTOR GRADER, 12M 3 AWD, N9P

MOTOR GRADER, 12M 3, N9R

ENGINE - MACHINE, C9, SYE

PACKAGE, 3.4B IOPU, CJ3

BROOM-ANGLE, SAHL BROOM, H1W

GENERATOR SET, 3516C, JDH

EXCAVATOR, 336F LH, KGH

MARINE ENGINE, C140-16, P3P

ENGINE - MACHINE, C9, SSE

EJECTOR TRUCK, 730C, TFH

ARTICULATED TRUCK, 725C, LFB

MINI HYD EXCAVATOR, 300.9D, LJ2

MOTOR GRADER, 140M 3 AWD, N9J

EXCAVATOR, 336F H, NAJ

EXCAVATOR, 320E, SHX

WHEEL TRACTOR-SCRAPER, 627K LRC, WTN

BROOM-ANGLE, SAHL BROOM, BAW

EXCAVATOR, M317D 2, CH5

EXCAVATOR, 336E H, HDW

ARTICULATED TRUCK, 730C, LFF

EJECTOR TRUCK, 730C, LFH

MINI HYD EXCAVATOR, 301.7D, LJ4

MINI HYD EXCAVATOR, 302.7D, LJ7

MOTOR GRADER, 160M 3, N9E

ENGINE - MACHINE, C9.3, SYE

ARTICULATED TRUCK, 730C, TFF

WHEEL TRACTOR-SCRAPER, 627K, WTC

EXCAVATOR, 336E LH, JEA

MINI HYD EXCAVATOR, 302.4D, LJ6

MOTOR GRADER, 160M 3 AWD, N9T

ENGINE - MACHINE, C13, T4F

TRACK-TYPE TRACTOR, D6R, WBC

GENERATOR SET, 3516, JCW

MINI HYD EXCAVATOR, 301.4C, LJ3

MINI HYD EXCAVATOR, 302.2D, LJ5

MOTOR GRADER, 12M 3 AWD, N9B

MOTOR GRADER, 140M 3 AWD, N9G

MOTOR GRADER, 160M 3 AWD, N9K

WHEEL TRACTOR-SCRAPER, 621K, WTA

WHEEL TRACTOR-SCRAPER, 623K LRC, WTM

GENERATOR SET, 3516B, JDE

GENERATOR SET, 3516C, JDJ

EXCAVATOR, 336F LNH, MTW

MOTOR GRADER, 140M 3, N9D

EXCAVATOR, 336F LH, PFL

TRACK-TYPE TRACTOR, D6N OEM, SC6

ENGINE - MACHINE, C9.3, SSE

WHEEL TRACTOR-SCRAPER, 623K, WTB

STW Service

Report

The

STW Service Report is a tool to help you collect, report, and organize your

service jobs.

-

Allows for complete documentation of your repair.

-

Reduce duplicate typing of Service Reports

-

Easy to read

-

Spell check

Easy integration with Dealer

Business System (both DBS and DBSi):

Download

header information from DBS

Upload

service information to DBS after your job is completed

Collect information from other

service tools, including:

Parts

lists from SIS

ECM

summaries and reports from Cat ET

Inspection

lists from Technical Analysis (TA)

Component Based

Troubleshooting

Component

Based Troubleshooting (CBT) helps the technician troubleshoot symptoms and codes

for Caterpillar engines and machines. After identifying a symptom, the

technician is presented with a list of components that, if not operating

properly, may cause the symptom. By using the information provided for each

component, the technician can identify the root cause of the symptom and fix the

problem. The technician is also presented with a list of available ECMs and

codes for the selected model to troubleshoot diagnostic codes. In addition, CBT

gives the technician links to related information for symptoms and codes in the

Service Information System (SIS).

0 Stars of 5,0 Reviews.

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

Share your thoughts with other customers.

Write a reviewYou may also like

-

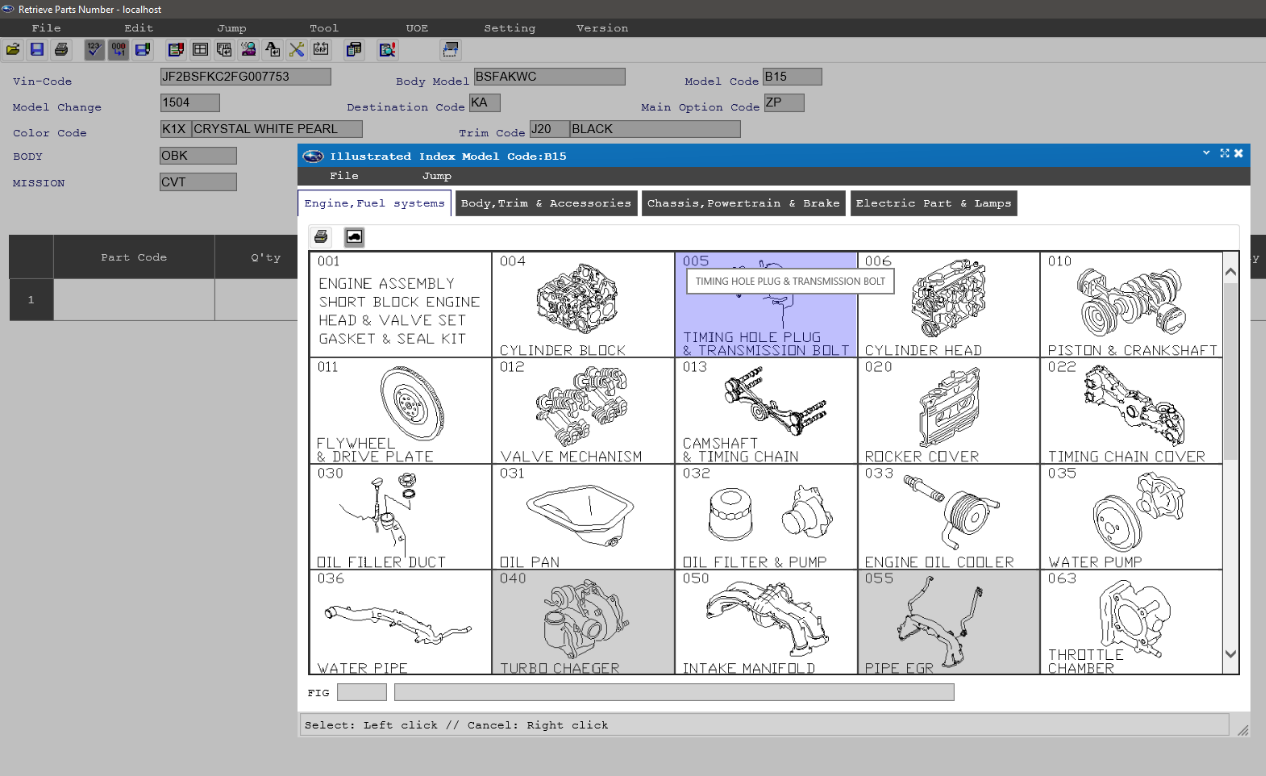

SUBARU EUROPE GENERAL EPC PARTS CATALOG 2021.10

$89.0018% off

-

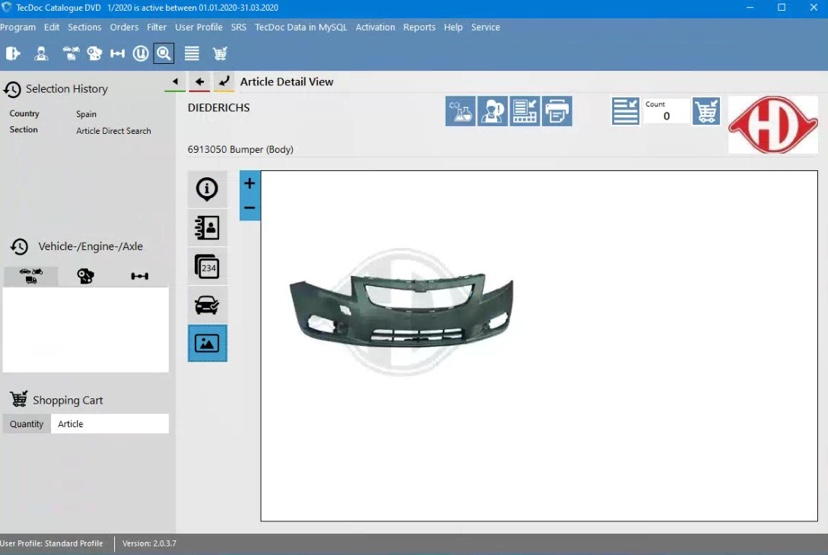

TecDoc Catalog DVD 1Q.2020 Full Offline 1 PC Install

$99.009% off

-

Tolerance Data 2009.2

$25.0014% off

-

AIRBAG Crash Killer 7.8.4 Crash Data from ECU Dumps Service Tool for Toyota FOR Renault Car Software Online PK Renolink

$119.008% off

-

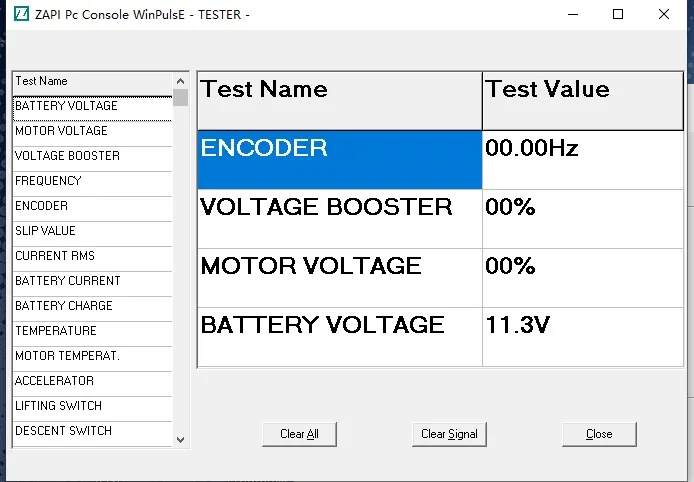

ZAPI F01183A Data Cable Zapi Console Software

$79.0020% off

-

Suzuki Worldwide EPC5 2019.05 Parts Catalog

$89.0018% off

-

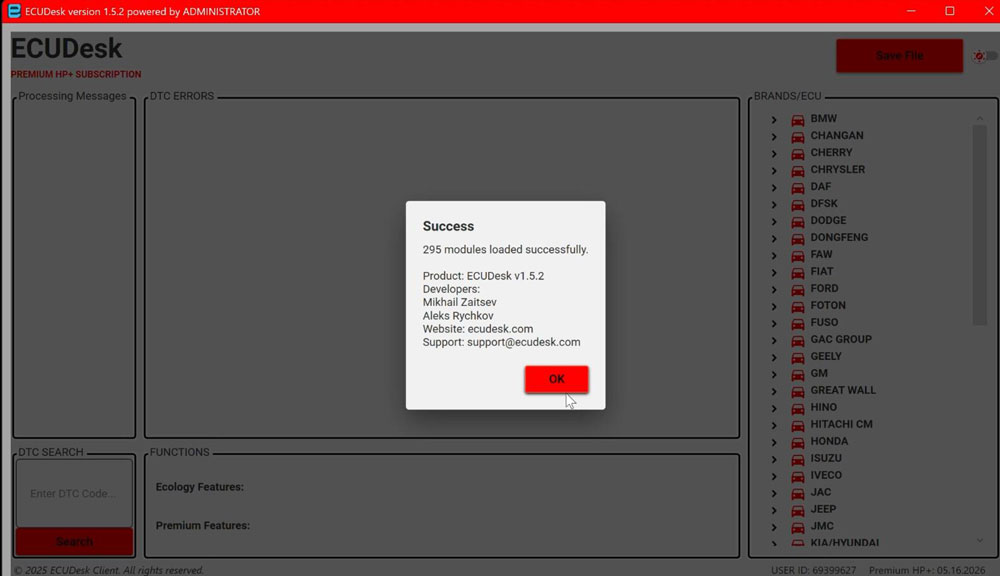

ECUDesk HP+ Version Stage1 ECU Tuning Software

$1500.004% off

-

Tel

+86-19892834301 -

WhatsApp