- WhatsApp:+86-19892834301

- Email: automantool@hotmail.com

- Skype:autoobdtop

Original Linde Forklift Truck 3903605140 Original LINDE CANBOX III Linde Bluetooth Service Box Diagnostic Interface Tool

0 out of 50 global ratings

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

ratings| answered questions

0 global ratings

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

Fast Shipping & No Tax

US Check: Ship from US

UK Check: Ship from UK

EU Check: Ship from Czech

Looking for help? Please contact Whatsapp: +86-19892834301

- Shipping:

-

Free Shipping

Express Shipping ServiceEstimated delivery time: 3-5 Working Days

- Quantity:

- Stock:28

- Weight:

- 0.7 KG

- Package:

Related Download Files

Original Linde Forklift Truck 3903605140 Original LINDE CANBOX III Linde Bluetooth Service Box Diagnostic Interface Tool

Requirements:

- O.S.: Windows XP;

Windows Vista; Windows 7; Windows

8

- CPU: Pentium/Athlon

1.8 GHz or higher

- RAM: 256 MB of system

memory

- Hard Drive: 15 GB of

available space

-

DVD-ROM

Original new fully functional LINDE CANBOX III

Bluetooth 7 pin cable

included

Basic functions of the

Linde Truck Can Box:

1.Diagnosis - to read

memory faults stored in the drivers of vehicles while allowing deleting, saving

and printing of error codes to the full

description.

2.Measured values - is called. LiveData or display current data from sensors or actuators registered by the driver.

3.Identifying Drivers - it displays detailed data such as. The serial number, software version, manufacturer's numbers, the numbers of character, etc ...

4.Actuator Test in other words starting components are direct tests performed on the elements of such systems. Launch ABS modulators, such as activation of the solenoid valves. Lifting - lowering the vehicle or machine. This part of the diagnostic otherwise known as active allows, for example. In the case of the engine to balance / detachment cylinders which in turn is helpful for example. In the evaluation of compression.

5.Calibrations are adaptations of the individual elements, eg. The sensors on the needs of the vehicle can be an example of calibration - to adapt the electronic throttle, pedal acceleration sensor active suspension, support systems, etc ...

6.Adjustments / Coding / Programming reconfiguration are all kinds of settings, eg. Off speed limiters, power, torque, activate hidden features, disable the exhaust gas treatment, etc. * (To do some reconfiguration is to have a conical expansion called optional extras. Developer like. calculators encodings or configuration).

7.Read / Write driver configuration - this allows you to copy the configuration of drivers during the replacement or repair.

8.Deleting maintenance / inspection service - functions help you review the service intervals (reset service light, oil, mileage, etc.)

All the above features allow for comprehensive diagnosis elements, eg such as:

engine

gearboxes

brake

systems

air conditioning

systems and heating /

reheating

retarder,

active

suspension

anti-theft

devices

central

computer

tachograph

dashboard

air processing, eg.,

SAC,

heater, dryer,

etc.

flue gas

treatment

steering eg.

EMAS

frame

modules

list of available

drivers could be replaced, however long it is dependent upon the vehicle

diagnosis equipment or machine.

For example, select the appropriate driver. Engine computer can, for example :

- Read pending diagnostic trouble codes (DTC)

- Read diagnostic trouble codes (DTC)

- Erase codes and turn off the "Check Engine" (MIL)

- The ability to save the read data to a file for later analysis

- Diagnosis of type damper actuator valves, sensors

- Dynamic control of ignition, starter dose,

- Engine speed (RPM)

- Order (Calculated Load Value)

- Coolant temperature (Coolant Temperature)

- The status of the fuel system (Fuel System Status)

- Speed of the vehicle (Vehicle Speed)

- Short-term correction injection time (Short Term Fuel Trim)

- Long-term correction of the injection time (Long Term Fuel Trim)

- Vacuum in the intake manifold (Intake Manifold Pressure)

- Ignition timing (Timing Advance)

- The temperature of the intake air (Intake Air Temperature)

- Air flow - an indication of the flowmeter (Air Flow Rate)

- Throttle position TPS (Throttle Position Absolute)

- Indicate the oxygen sensor (Oxygen Sensor Voltages / associated short term fuel trims)

- Fuel pressure (Fuel Pressure)

- Checking the

condition of the engine based on the consumption of individual cylinders -

that

difference in fuel

doses dispensed by the computer to the individual

cylinders.

- Measurement of vehicle parameters - power and acceleration

and many other troubleshooting steps are impossible to comply with universal testers ...

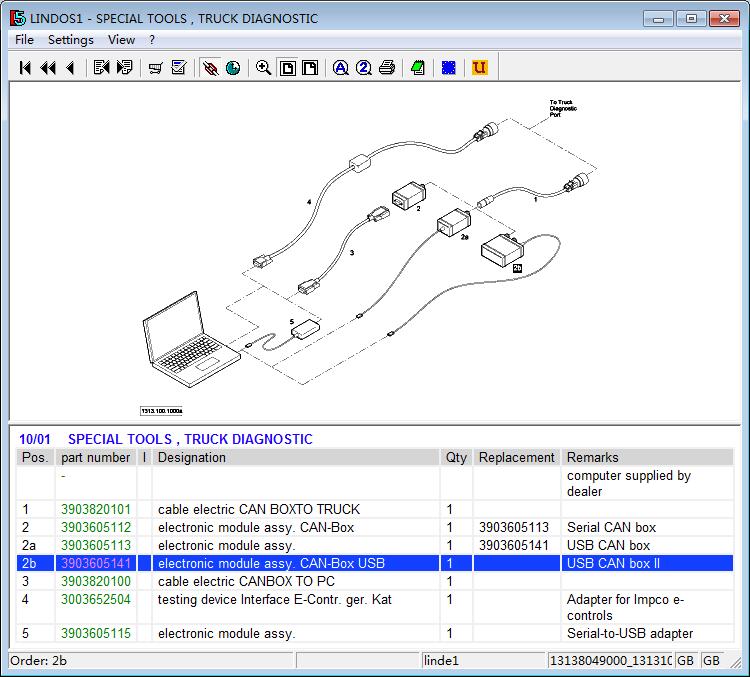

Software Display:

CanBox + Pathfinder (diagnostic software) can be use on following truck model:

E

Serial

BR 335-03( 1.4.0 ,

Linde MH-D)

BR 346( 1.9.0 , Linde

MH-D)

BR 386( 1.19.0 , Linde

MH-D)

BR 387( 1.7.0 , Linde

MH-D)

BR 388 ( 1.4.0 , Linde

MH-D)

LSP -Linde Safety Pilot

( 1.0.0 , Linde

MH-D)

H

Serial

BR 1313( 1.7.0 , Linde

MH-D )

BR 1401( 1.0.0 , Linde

MH(UK) Ltd)

BR 350 ( 1.13.0 , Linde

MH-D )

BR 359 ( 1.13.0 , Linde

MH-D )

BR 391 ( 1.14.0 ,Linde

MH-D )

BR 392 ( 2.18.0 Linde

MH-D )

BR 392-02 ( 1.1.0 Linde

MH-D )

BR 393 ( 2.15.0 , Linde

MH-D )

BR 393-02 ( 1.1.0 ,

Linde MH-D )

BR 394 MPR ( 1.4.0 ,

Linde MH-D )

BR 394 ( 2.15.0 , Linde

MH-D )

BR 394 -02( 1.1.0 ,

Linde MH-D )

BR 396 ( 1.10.0 , Linde

MH-D )

BR 396-02 ( 1.1.0 ,

Linde MH-D )

LPF30 ( 1.2.0 , Linde

MH-D )

Cummins QSB Tier2 (

1.4.0 LMH-D )

Cummins QSB Tier3 (

1.4.0 LMH-D )

Deutz – EMR3 ( 1.6.0

,Linde MH-D )

Deutz – EMR4i ( 1.2.0

,Linde MH-D )

IMPCO ( V1.9.0 ,Linde

MH-D )

VW CR ( 1.2.0a ,Linde

MH-D )

VW P-D ( 1.5.0 ,Linde

MH-D )

VW- Motordiagnose (

2.13.0 , Linde MH-D

)

P,W

Serial

BR 1189 ( 1.4.0 , Linde

MH-F )

BR 1190 ( 3.3.0 , Linde

MH-F )

BR 127-02 ( 1.7.0 Linde

MH-D )

BR 127-03_04 ( 1.5.0

Linde MH-D )

R

Serial

BR 1120 ( 1.3.0 , Linde

MH-D )

BR 1123 ( 1.8.0 , Linde

MH-D )

BR 115-02 ( 2.17.0 ,

Linde MH-D )

BR 115-03 (1.13.0 ,

Linde MH-D )

BR 115-11/12 (1.8.0 ,

Linde MH-D )

BR 116 ( 1.15.0, Linde

MH-D )

BR 116-02 ( 1.12.0 ,

Linde MH-D )

BR 116-03 ( 1.5.0 ,

Linde MH-D )

T,N,L

Serial

BR 1111 ( 3.3.0 , Linde

MH-F )

BR 1151 ( 1.4.0 , Linde

MH-F )

BR 1152 ( 1.18.0 ,

Linde MH-F )

BR 1158 ( 1.4.0 , Linde

MH-F)

BR 1160 ( 1.2.0 , Linde

MH-F)

BR 1169 ( 1.4.0 , Linde

MH-F)

BR 1172 ( 1.17.0 ,

Linde MH-F)

BR 131 ( 3.3.0 , Linde

MH-F )

BR 132 ( 3.3.0 , Linde

MH-F )

BR 133 ( 3.5.0 ,Linde

MH-F )

BR 372 ( 1.9.0 , Linde

Material Handling

)

ParaDigFSx33 ( 3.4.3.2

, Still Wagner GmbH

)

V,K,A

Serial

BR 1110 (3.3.0 , Linde

MH-F )

ParaDig13-3_15-3_AC

(2.05, KION Warehouse Systems GmbH)

ParaDig13-3_15-3_DC

(2.05, KION Warehouse Systems GmbH)

ParaDigBLS (2.07, KION

Warehouse Systems GmbH)

ParaDigELK (2.07, KION

Warehouse Systems GmbH)

ParaDigHPS_ManUp (2.07,

KION Warehouse Systems GmbH)

ParaDigHPS_MD-MU_4

(2.07, KION Warehouse Systems GmbH)

ParaDigIOX (2.02, KION

Warehouse Systems GmbH)

ParaDigIZF (2.10, KION

Warehouse Systems

GmbH)

ParaDigLR80 (2.01, KION

Warehouse Systems

GmbH)

ParaDigManDown_4 (2.21,

KION Warehouse Systems

GmbH)

ParaDigManDown (2.13,

KION Warehouse Systems

GmbH)

ParaDigManDown10 (2.05,

KION Warehouse Systems

GmbH)

ParaDigManUp_2 (2.13,

KION Warehouse Systems

GmbH)

ParaDigManUp_4 (2.24,

KION Warehouse Systems

GmbH)

ParaDigManUp (2.06,

KION Warehouse Systems

GmbH)

ParaDigManUp1013N

(2.05, KION Warehouse Systems

GmbH)

ParaDigOrderPick_X

(2.19, KION Warehouse Systems

GmbH)

ParaDigOrderPick (2.10,

KION Warehouse Systems

GmbH)

ParaDigPinCode_Disp_MD-MU (2.08, KION Warehouse

Systems GmbH)

ParaDigPinCodeManUp

(2.05, KION Warehouse Systems

GmbH)

ParaDigPinCodeOrderPick_X (2.05, KION Warehouse

Systems GmbH)

Xtra

Serial

CanBox (1.3.0,

LMH-D)

Flash_394-02 (2.0.0a,

Linde MH-D)

Flash_396_LHC11 (1.2.0,

Linde MH-D)

Flash_396-02 (1.0.0,

Linde MH-D)

Flash_LAC03 (1.1.0,

Linde MH-D)

Flash_LAC03_61 (2.1.0,

Linde MH-D)

Flash_LES40 (2.1.0,

Linde MH-D)

Flash_LAC02_BR1152

(1.0.0, ServiceXpert

GmbH)

Flash_LAC02B_BR1172

(1.0.0, ServiceXpert

GmbH)

Packing List:

0 Stars of 5,0 Reviews.

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

Share your thoughts with other customers.

Write a reviewYou may also like

-

Original Still Canbox USB (OEM) 50983605400 original Still forklift Canbox interface with software still steds 8.14/8.20

$1249.004% off

-

2025A CAT Caterpillar ET 4 Diagnostic Adapter IV CAT ET Diagnostic Tool Plus Lenovo T450 Laptop Ready to Use

$759.005% off

-

Deutz Diagnose Kit For Deutz Engine Communicator Deutz Decom Truck Diagnostic Scanner Plus Panasonic CF19 I5 Laptop

$1399.007% off

-

Bobcat Service Analyzer BOBCAT DIAGNOSTIC Tool (RST) Service tool harness Remote Start Tool Plus Panasonic CF53 Laptop Ready to Use

$2059.005% off

-

2025.12 V3 Noregon JPRO Professional Truck Diagnostic Scan Tool Plus Panasonic CF19 I5 4GB Laptop

$959.002% off

-

16A68-00500 Diagnostic Cable For Mitsubishi Lift Trucks

$268.004% off

-

Tel

+86-19892834301 -

WhatsApp