- WhatsApp:+86-19892834301

- Email: automantool@hotmail.com

- Skype:autoobdtop

368A Key Cutting Duplicated Machine Locksmith Tools Key Machine 220W

0 out of 50 global ratings

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

ratings| answered questions

0 global ratings

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

Fast Shipping & No Tax

US Check: Ship from US

UK Check: Ship from UK

EU Check: Ship from Czech

Looking for help? Please contact Whatsapp: +86-19892834301

- Shipping:

-

Free Shipping

Express Shipping ServiceEstimated delivery time: 3-5 Working Days

- Quantity:

- Stock:41

- Weight:

- 8.3 KG

- Package:

Related Download Files

368A Vertical Car Household Key Copy Cutting Dulplicated Machine Locksmith Picking Tool 220V

TOP

4 Reasons to Get 368A Key Copy Cutting

Machine:

1.

Multi functional practical machine, equipped with horizontal feeding movable

handle

2.

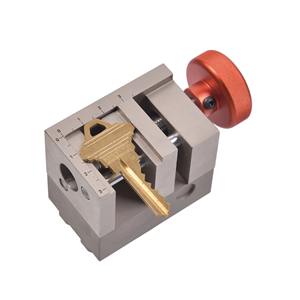

Multifunctional steel fixture, can copy various hollowness type,wave

type,cylindrical key and key for multi lock and composite bead keys and some car

keys,such as BMW,HONDA,Volkswagen car keys

3.

Fixture with dark key duplication service pitch line and cylinder type key

assembly function (multifunctional clamp)

4.

With hardened ball bearing slide mechanism.

386A Key Copy Cutting Machine

Reviews:

I

bought a defu 368a key copy machine because really cheap and it works good on

many types of key

368A Key Copy Cutting

Machine Parameters:

Power:

220V/50hz

Dimension size: 30

*21*35cm

Weight: 10kg (Volume

weight)

Voltage:

110V~220v

Frequency:

50/60Hz

Plug Type:

UK.USA.BR.CN.EU

1pc x 368A Key Cutting Machine

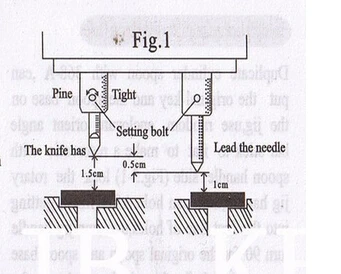

The change of the cutter and leading needle:

1.Use inner hexagonal wrench to unclamp the regular screw anticlockwise direction.

2.Draw out the cutter and the lead needle downward,separate them from axis.

3.Insert the new cutter and leading needle in the axis,when suitable for in its flexble position(Fig.1),fix the screw to lock in clockwise

direction with inner hexagonal wrench.

Note: Cutter and lead needle must the same angle(hole type cut) or the same diameter(wave type cut), otherwise it is inaccureate to duplicate.

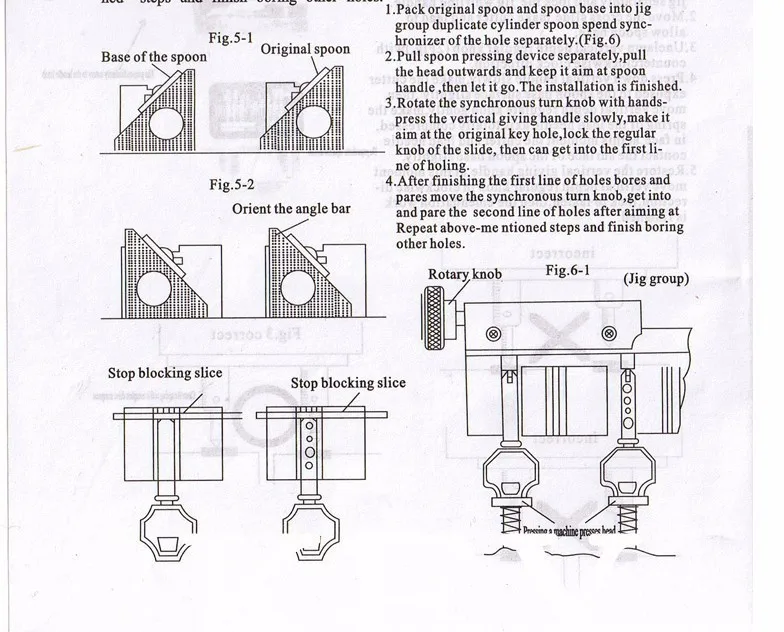

2. Pull spoon pressing device separately,pull the head outwards and keep it aim at spoon handle,then let it go.The installation is finished.

3. Rotate the synchronus turn knob with handspress the vertical giving handle slowly,make it aim at the original key hole,lock the regular

knob of the slide,then can get into the first listen of holing.

4. After finishing the first line of holes bores and pares move the synchronous turn knob,get into and pare the second line of holes after aiming at repeat above-me ntioned steps and finish boring other holes.

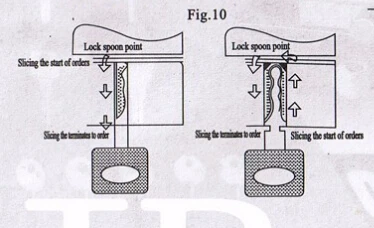

The cannelure reaming boring and paring

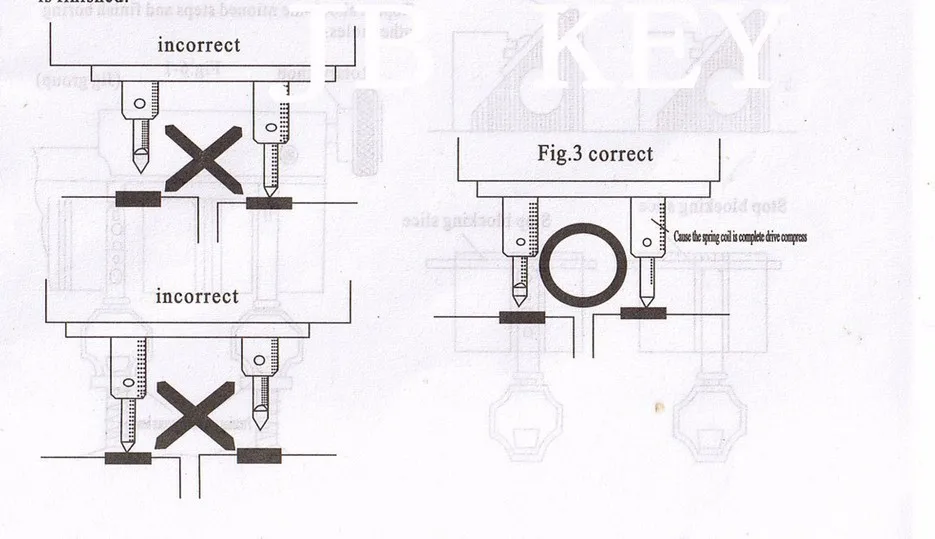

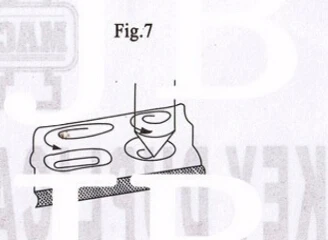

As the concave nest of the key is grater than leading needle or boring and paring the oval concave nest, it need to carry on reaming and bore paring at this moment,when reaming is pared,the cross slide should move slowly in the counterclockwise clock direction(Fig.7),If the direction of the cross slide is wrong, it may easily to have damaged cutter.

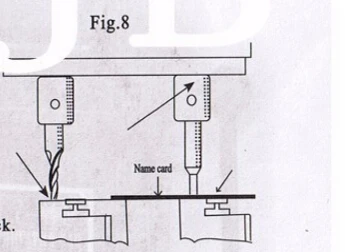

1.Install the leading needle,and lock the regular srews.(Fig.1)

2.Move the verical depth buttons in clockwise direction(consults Fig.2) till the spring is totally compressed.

3.Fetch a name card(thick about 0.2) and put it on the surface of the jig under the leading needle.

4.Put the cutter into axis hole,hen press the vertical giveing handle slowly,make the name card happen to be pressed during leading needle and jig.

5.Pull down cutter gently,make terminal surface of the cutter and jig surface contact ench other

then lock cutter's regular screw along the direction of the clock.

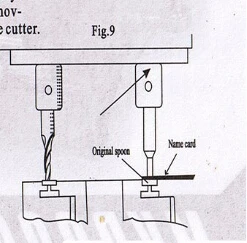

6. Put the original key into the jig and lock the rotary handle of the jig.

7. Place one corner of name card on the cut part of original,then press down vertical giveing handles slowly, press one corne of name card on the cut part of leading needle and original spoon,then lock the vertical depth of regular screw along the direction of the clock,at this moment the vertical moving is totally dispelled(Fig.9)

8. Pack the jig into the base of the spoon,and move the handle of the jig,fasten it.

9. Starting the motor,move the cross slide moves in the wrong direction,It will damage the cutter.

0 Stars of 5,0 Reviews.

- 5 stars:0%

- 4 stars:0%

- 3 stars:0%

- 2 stars:0%

- 1 stars:0%

Share your thoughts with other customers.

Write a reviewYou may also like

-

Tel

+86-19892834301 -

WhatsApp